Menu

X

- No products in the list

This success story explores the application of heat treating products in advanced Freight and Tank Car Repair Techniques for the Railway Industry.

Goal:

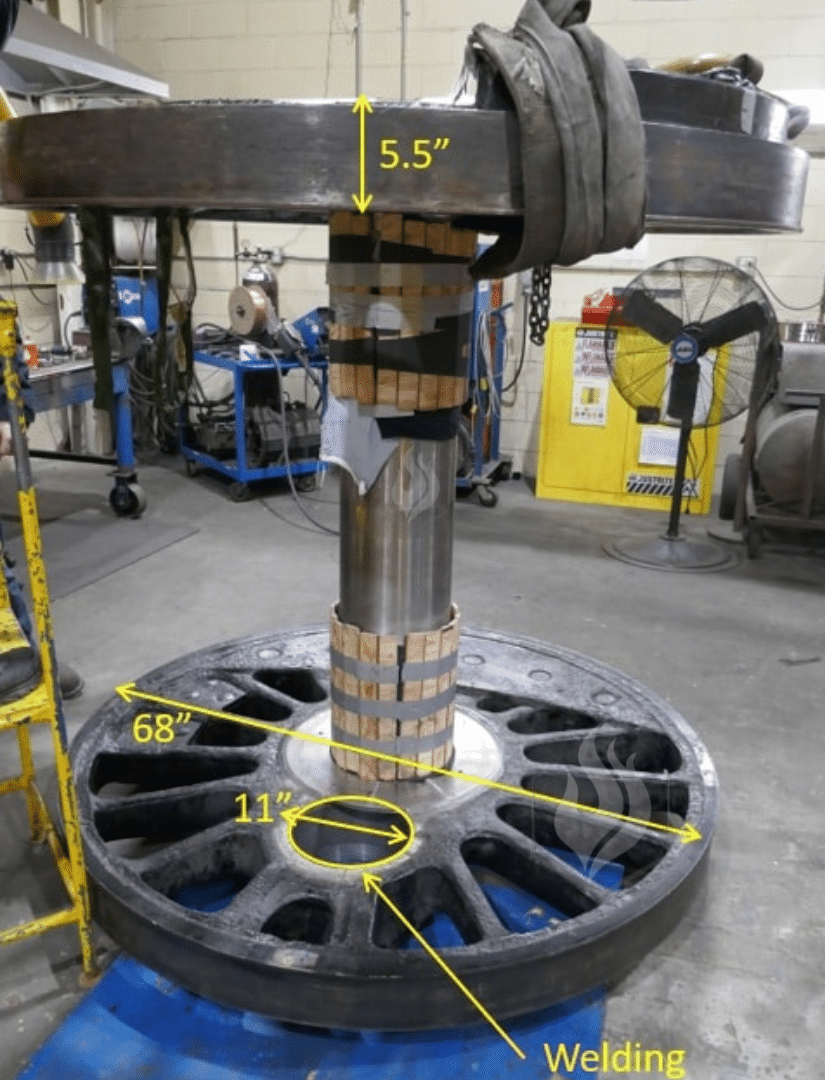

The client aimed for a solution that prioritized safety and cost-effectiveness, concentrating on strengthening structural resilience and extending overall longevity for components requiring repair. These components exceed the capacity of traditional pre-heating methods in a furnace.

Key Issue:

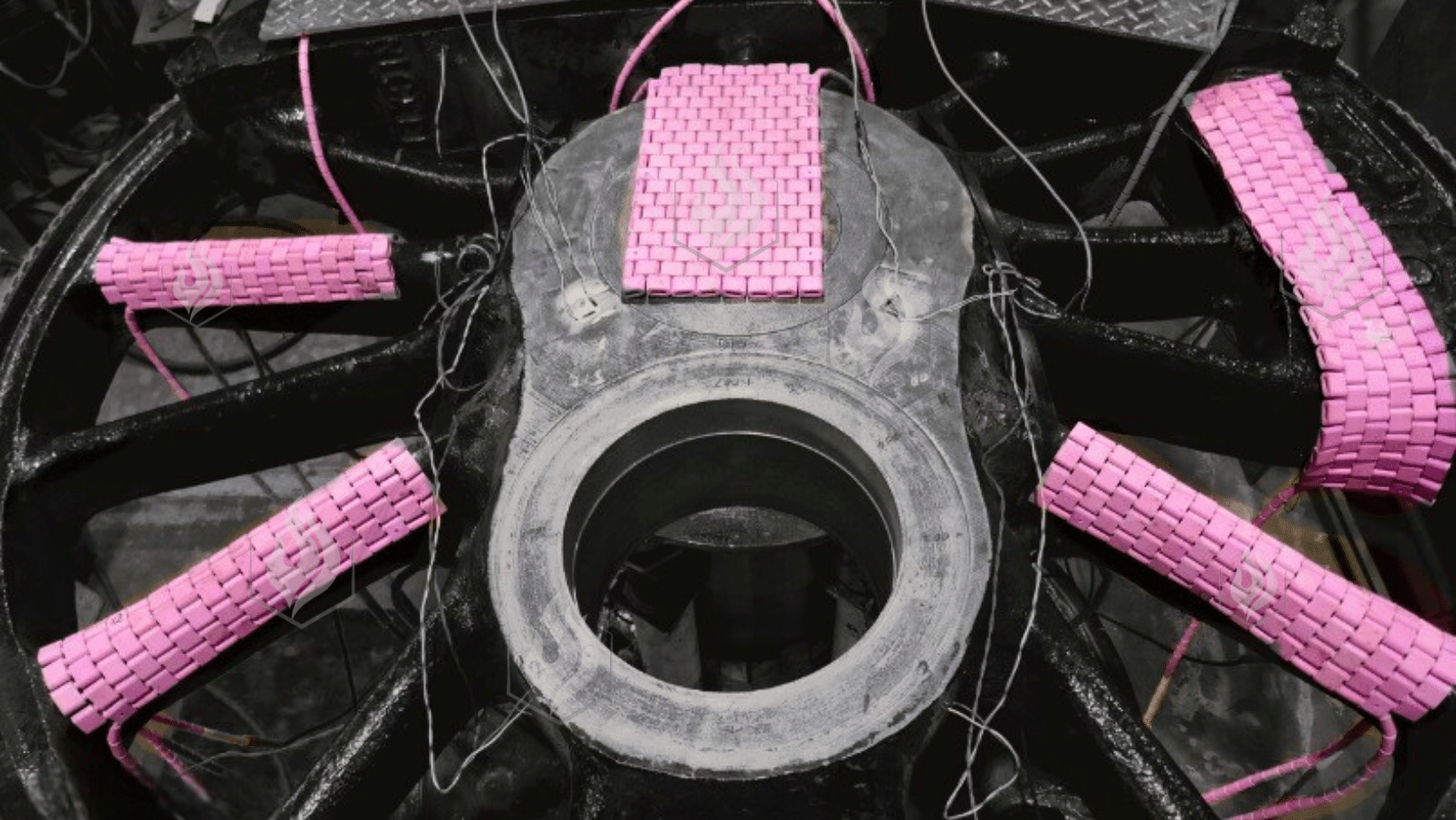

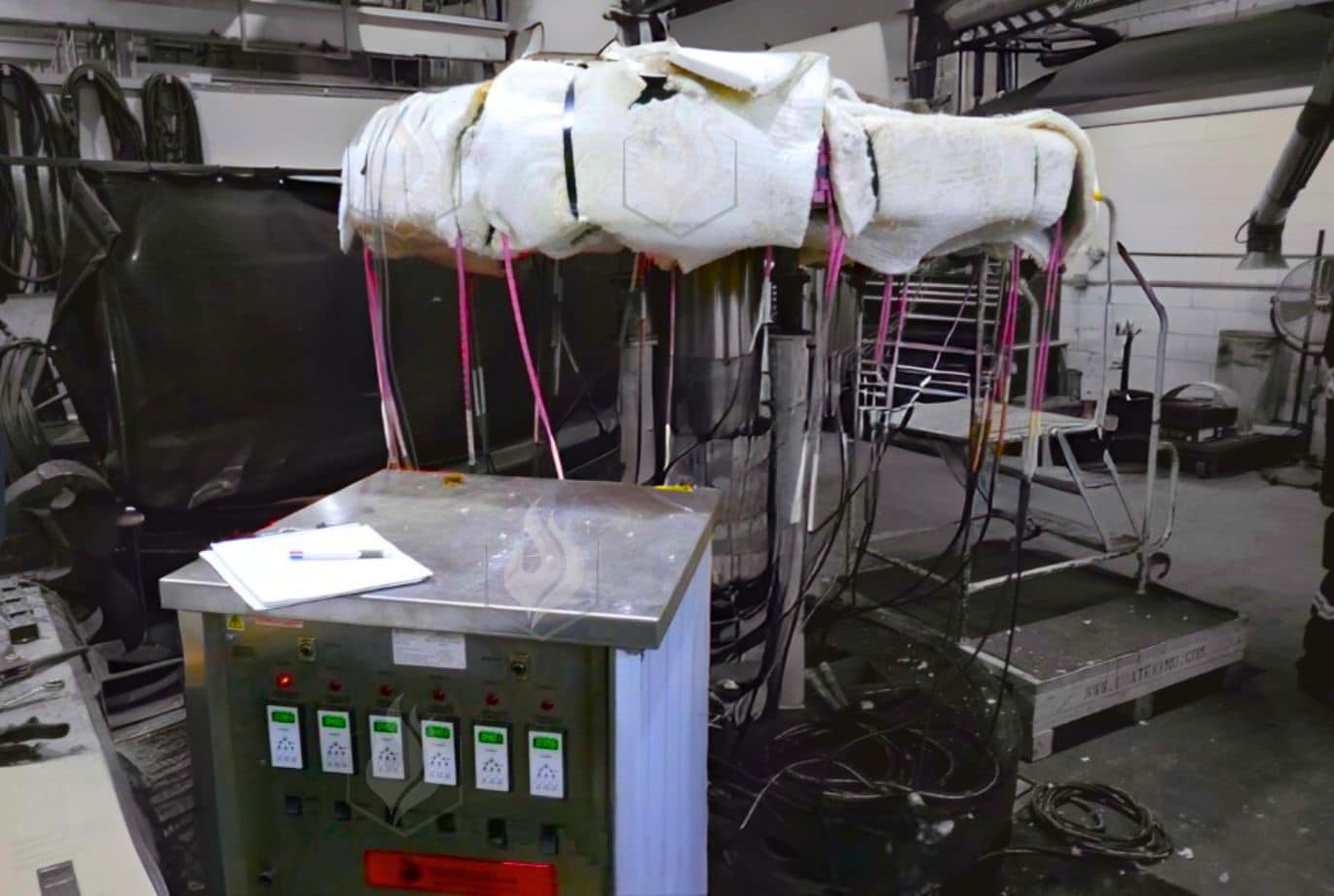

To meet the rail car repair challenge, we suggest utilizing Adaptable Mobile Resistance Heating technology with the Cooperheat console. This solution incorporates 18 flexible ceramic pads, a stud welder, and thermal insulation, providing on-site versatile and efficient approach to repairs.

Utilizing Adaptable Mobile Resistance Heating with the Cooperheat console streamlined rail car repairs. Our solution, including 18 flexible ceramic pads, a stud welder, and thermal insulation, led to swift, safer, cost- effective repairs. This innovation proved highly effective, optimizing maintenance operations and establishing itself as a reliable solution for the rail car industry.

Yes for North America we have 600 volts (Canadain) 480 or 360 ( US) Easy to change the voltage setting from one to another.

See Video :

https://innovativeheattreatment.com/product/cooper-heat-console/

IHT didn't just offer us a one-size-fits-all solution; they tailored their services to fit our unique needs, resulting in a perfect outcome for our business.

After a year of working with IHT, it's clear they're more than a vendor; they're a strategic partner. Their ongoing support and innovation have been crucial to our growth.