About Us - Innovation

INTERNATIONAL DISTRIBUTION: SHIPS - NORTH AMERICA - 24 HOURS

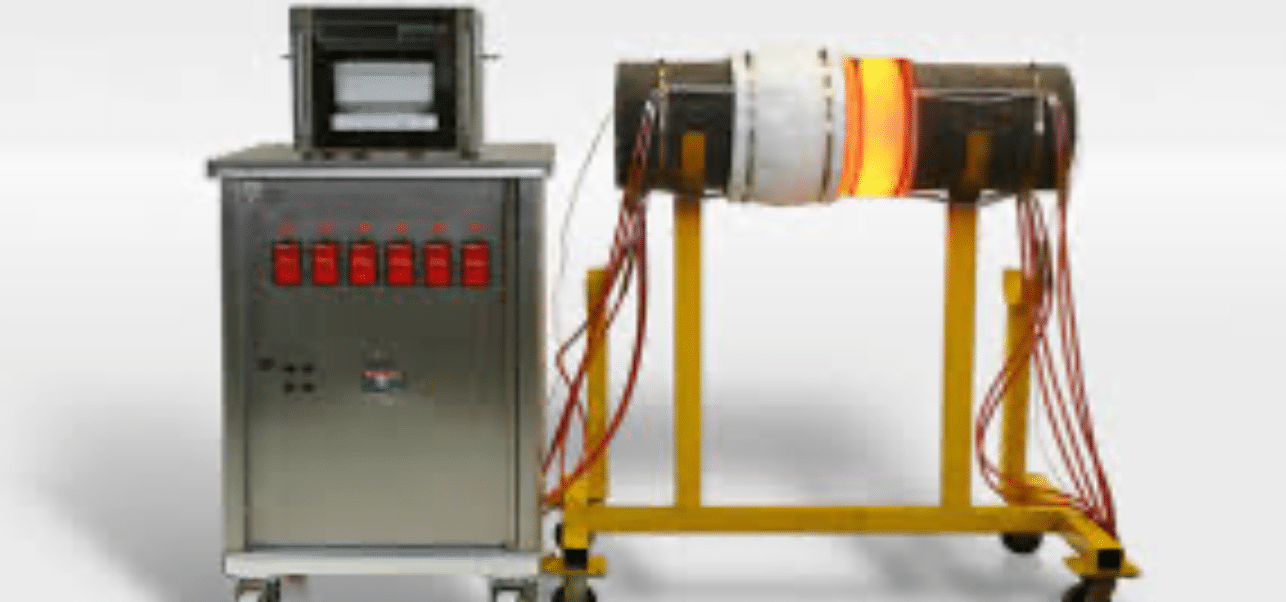

Heat Treatment

Innovative Heat Treatment – Our Primary Goal is to :

Provide INNOVATIVE HEAT TREATMENT SOLUTIONS TO OUR CLIENTS.

If your Company’s Heat Treatment goals are to have:

- . Quick turn around time on Stocked product

- Desire User Friendly products

- Waranty – That stands behind the Quaility of its Product- Three years

- Experienced – Customer Service – “THAT CARES”

Innovative Heat Treatment Inc. Corporate Office is in Calgary, Alberta , Canada.

We are a team of Industry professionals that are driven by the Innovation in the Heat Treatment Industry.

Many of the products presently in the Industrial Stress Relieving Industry were designed over fifty years ago and are not much different today then they were then.

We BELIEVE in THINKING DIFFERENTLY.

This was the catylst for the birth of “Innovative Heat Treatment Inc.”.

TWO MAIN TYPES OF HEAT TREATMENT

1. PRE- HEAT TREATING

Preheat is a term associated with the application of heat to metal component prior to and during welding.

There are a number of reasons that preheat may be required, including reduction of residual stresses after the component has been welded.

Minimising absorption of Hydrogen into the weld during welding.

Preheat temperatures are generally relatively low, ranging typically from 50 C up to 250 C.

2. POST WELD HEAT TREATMENT

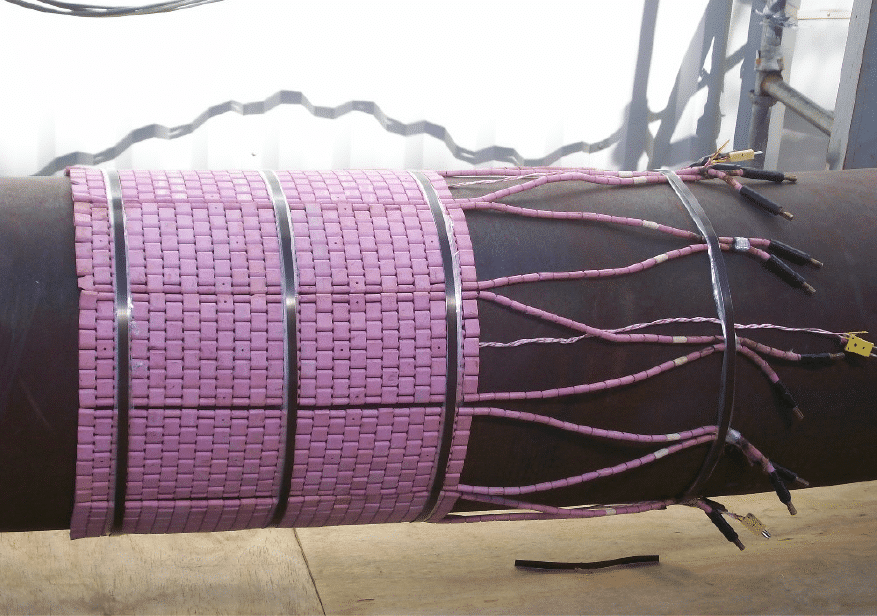

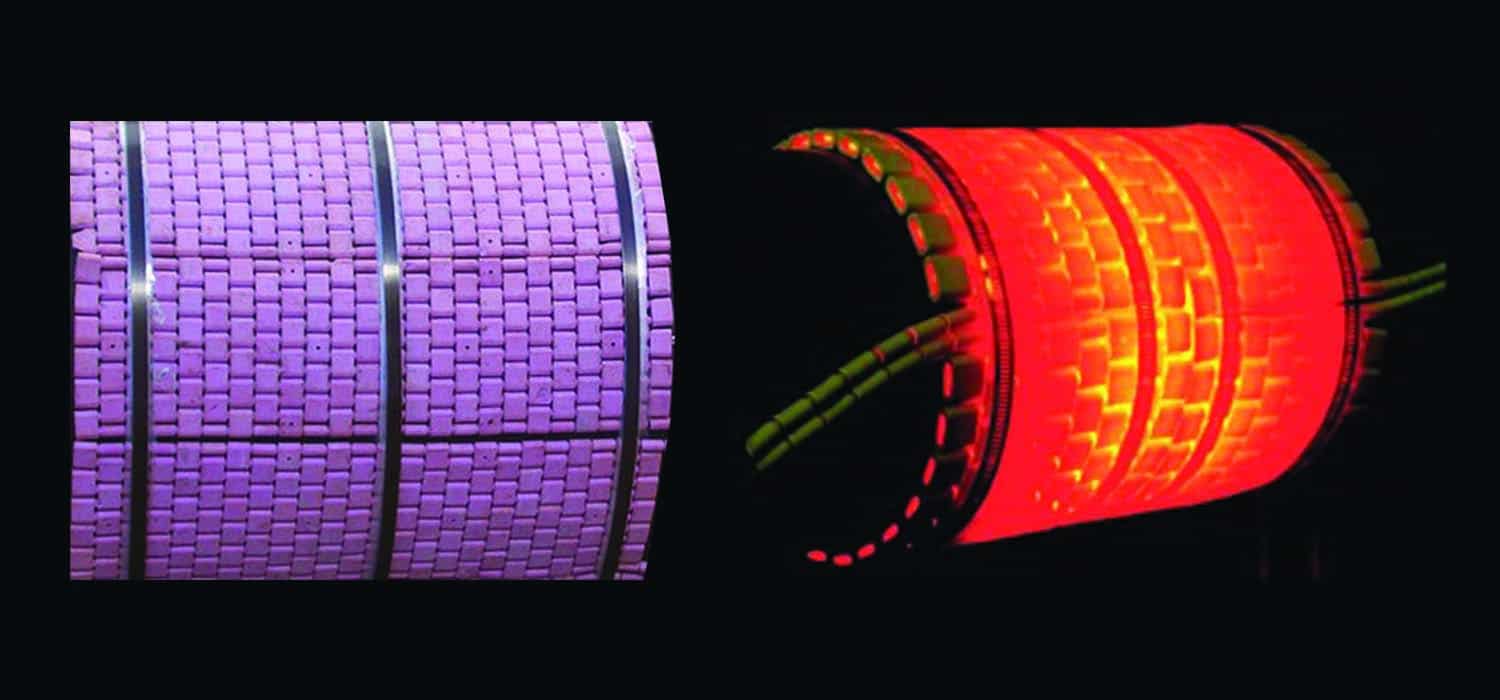

POST Weld Heat Treatment (PWHT) is a term used to describe the heating of an entire weld to a high temperature enough to reduce the residual stresses within the weld. PWHT temperatures are typically in the range of 600 C to 700 C.

There are a a variety of application methods for heat to weld geometrics in order to achieve the desired temperature, ranging from locally applied electrical heaters, to larger gas fired furnaces.

This method used is usually determined by the fabrication geometry, size, access restrictions and site constraints

Order Procedure

Registration

Leave the application on our website or by phone

The Confirmation

The manager will contact you for further details

Delivery

We will gladly deliver your order soon