Menu

X

- No products in the list

This case study explores the best methods for pre-heat treatment in the context of ship building repair and maintenance .

The primary goal is to innovate beyond conventional practices by

implementing a solution that reliably maintains Pre-Heat Temperatures, reinforces the structural durability of ship components.

The goal is to create a new welding procedure that minimizes the need for extensive pre- heat treatment .

The client’s challenge was to develop a regulatory-approved welding process suitable for the exotic low-temperature steel grade used in the hull construction.

The primary challenges included:

The development of a new Weld Procedure Specification (WPS) offers a practical and efficient solution for military shipbuilding, particularly when cold temperature toughness is critical. This WPS is designed for easy implementation in the field, eliminating the need for costly and time-consuming post-weld heat treatment.

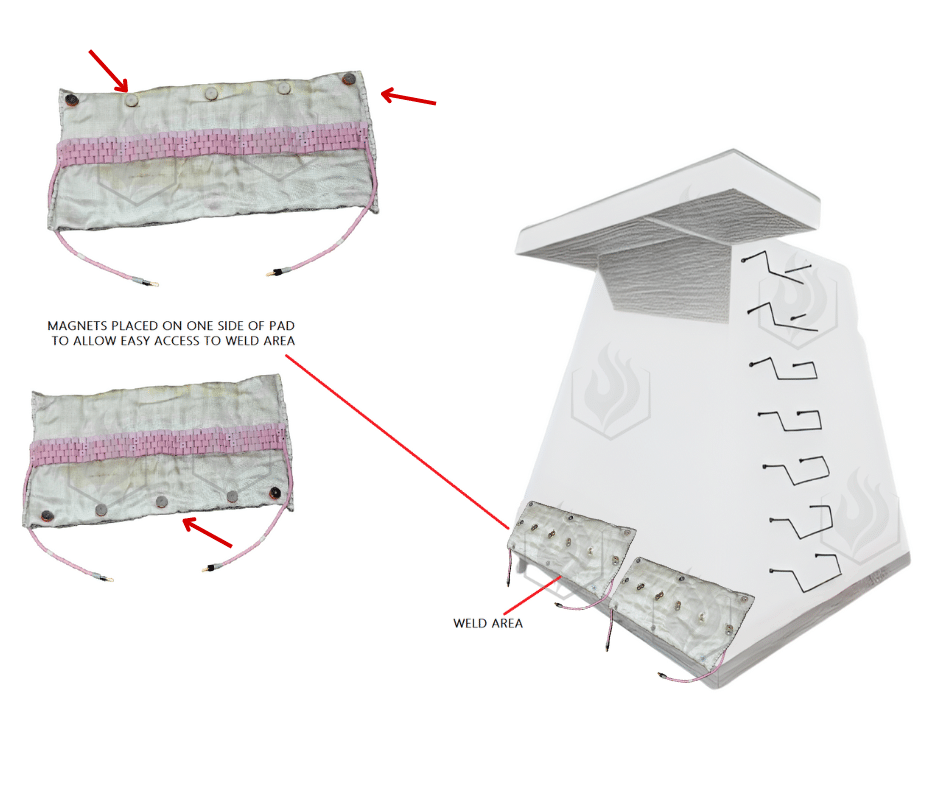

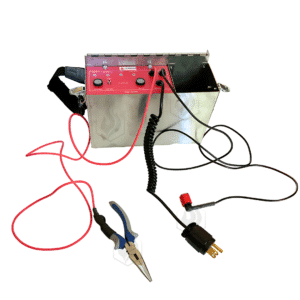

The solution utilizes the following advanced products:

This combination of products and the new WPS enables shipbuilders to achieve high-performance welds that meet stringent standards, while also improving efficiency and reducing overall project costs.

The products provided a practical and efficient solution for shipbuilding, particularly in achieving the required cold temperature toughness.

The solution proved to be easy to implement in the field, successfully reducing the need for costly and time-intensive heat treatment.

Key results include:

Overall, the combination of these advanced products and the new WPS allowed shipbuilders to achieve high-performance welds that met standards, while also increasing efficiency and significantly reducing project costs.