X

- No products in the list

Industries like oil and gas or steel, use heavy machinery assemblies that face extreme pressure and heat, causing wear over time.

This case study highlights the PWHT process used to repair a steel processing roller assembly, ensuring its durability and performance in harsh conditions.

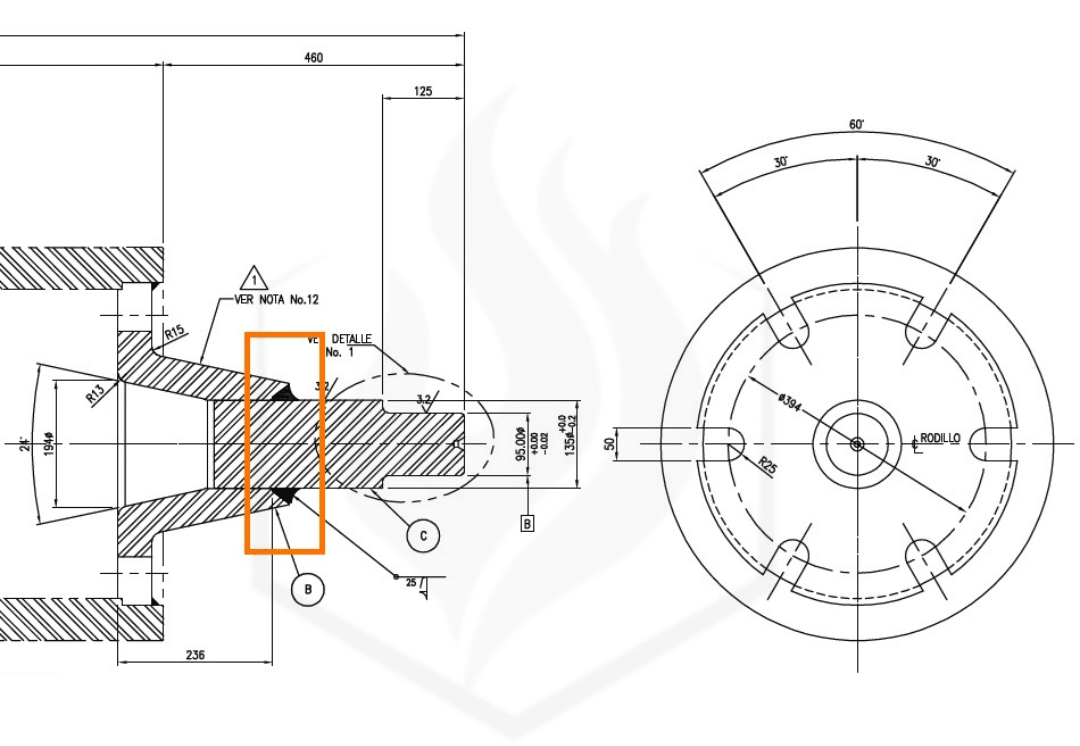

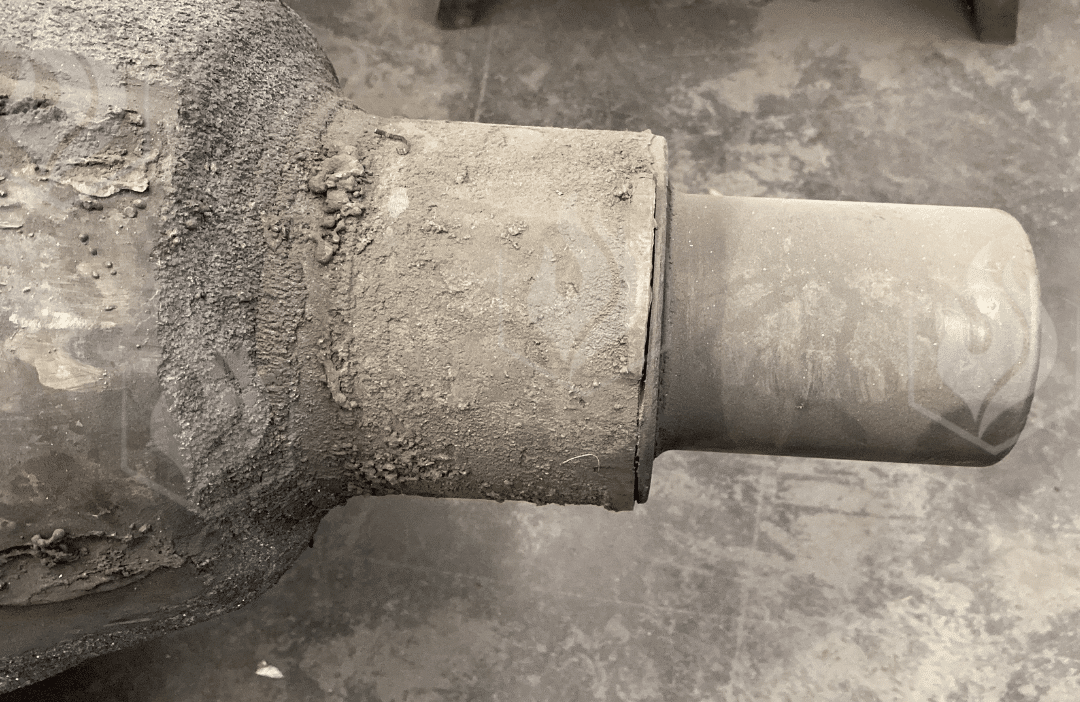

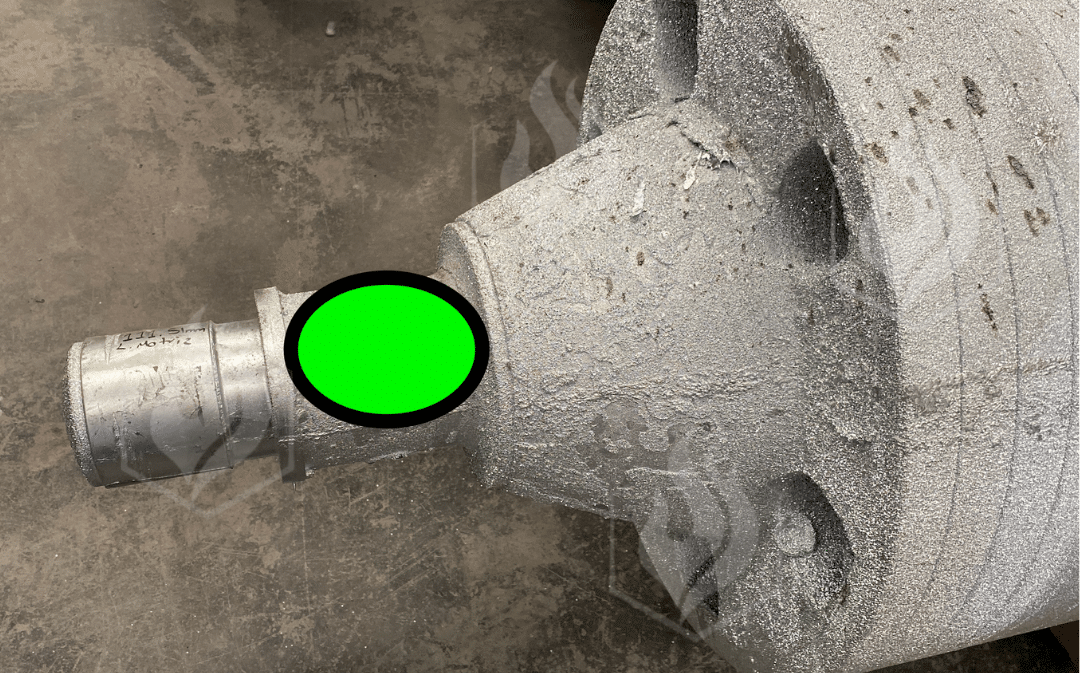

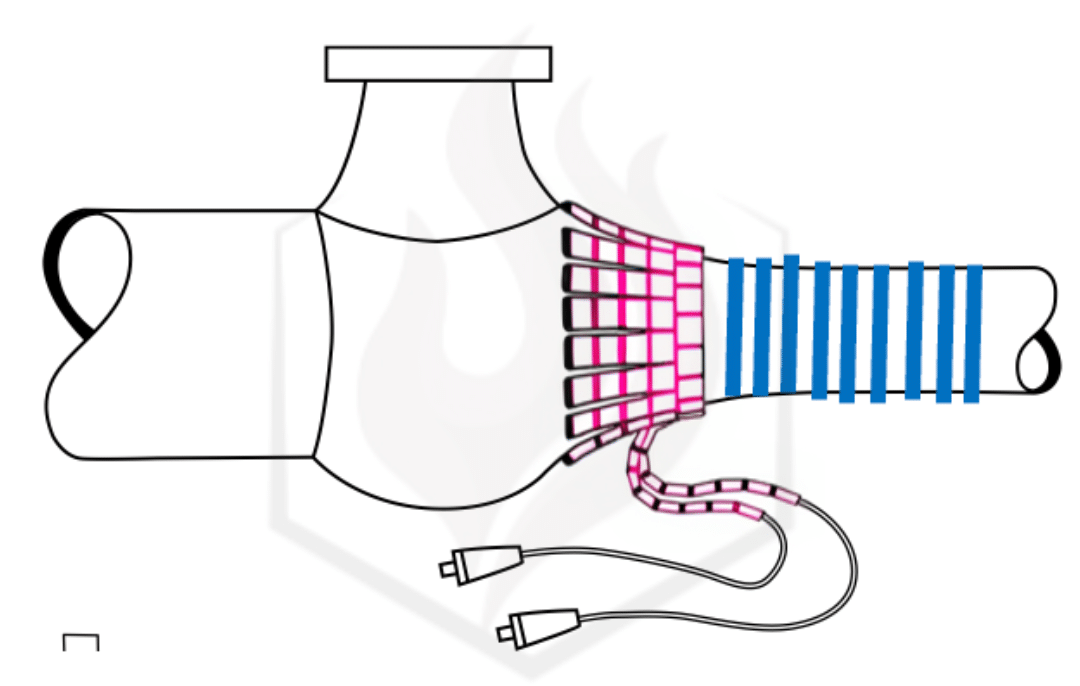

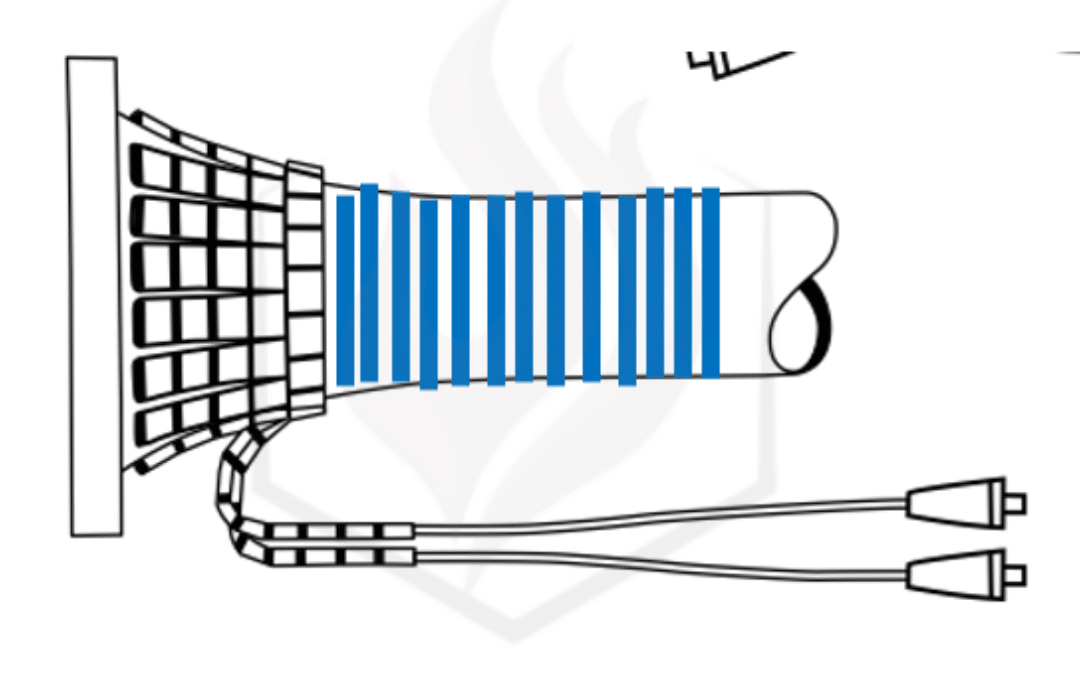

A roller assembly used in steel processing faced significant wear due to harsh operating conditions. Its cylindrical and flared design, typical of rolling mills, highlighted its key role in metal forming processes, requiring repair and reinforcement.

The specific challenge was performing PWHT on a small, pre-machined 145mm diameter stud after welding. This was crucial to strengthen the weldment before machining the stud to its final 135mm diameter.

Given the shape, texture, and design of the component, precise temperature control and treatment were necessary to maintain the integrity of the weld and avoid any distortions.

In order to address the challenge presented, we reccomended the following product solutions;

The clients approach involved the following heat treatment products and equipment:

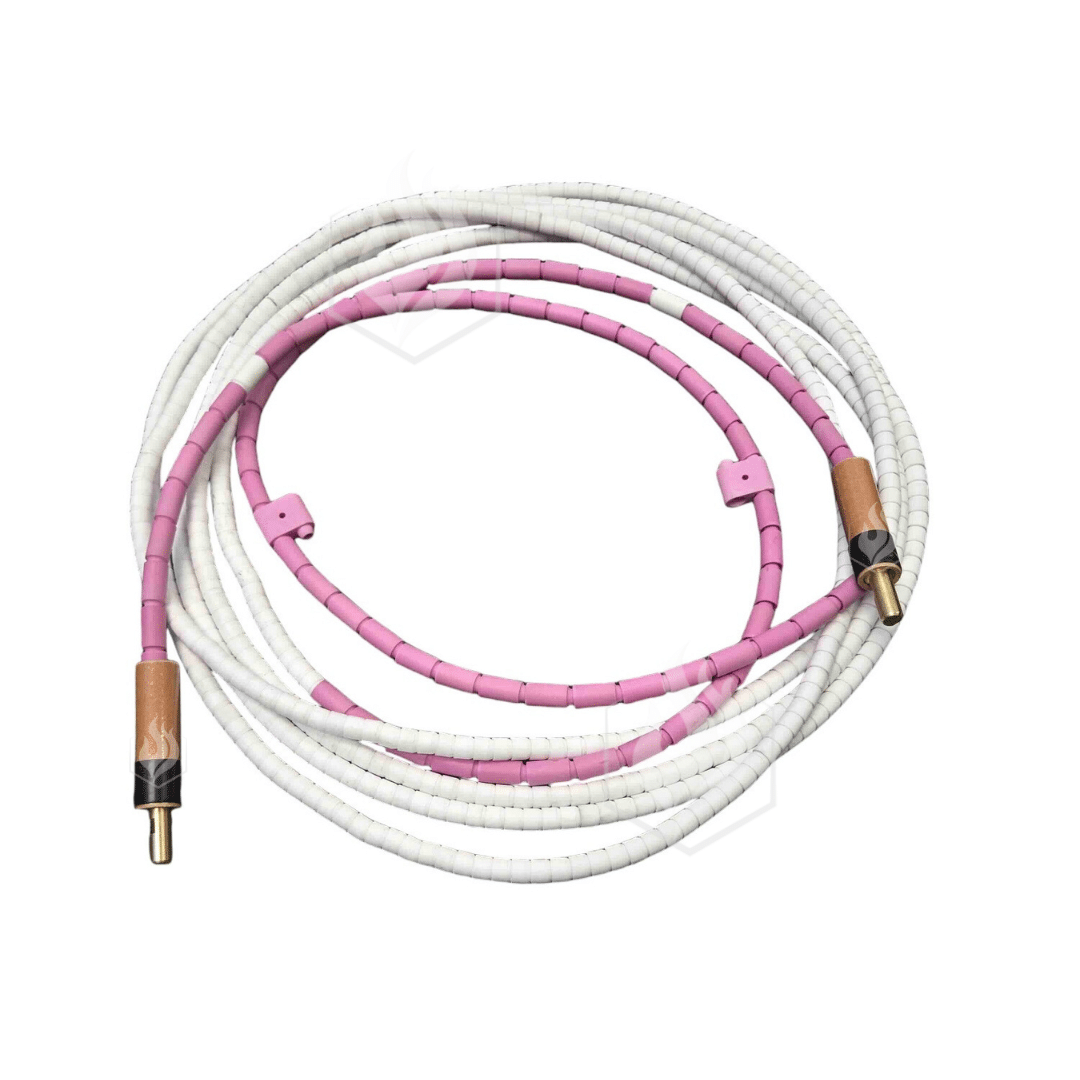

After testing various insulation materials, CooperKnit emerged as the top performer.

Unlike the others, CooperKnit mats and rolls were found to be the most efficient and sustainable solution for preheating steel pipes.

They provided:

Considerations with Other Insulations:

Super Wool: Usable only once or twice.

CCE Wool: Good price point but weak tensile strength.

Rock Wool: Bulky, hard to handle and set up, and usually reusable less than five times.

Teflon: Less cost-efficient and degrades more quickly.

The precise PWHT process successfully reinforced the weldment, enabling it to withstand the demands of steel processing. After heat treatment, the stud was machined to its final 135mm diameter with weld integrity preserved. The roller assembly was ready for continued operation in steel mills, oil rigs, and heavy machinery applications.

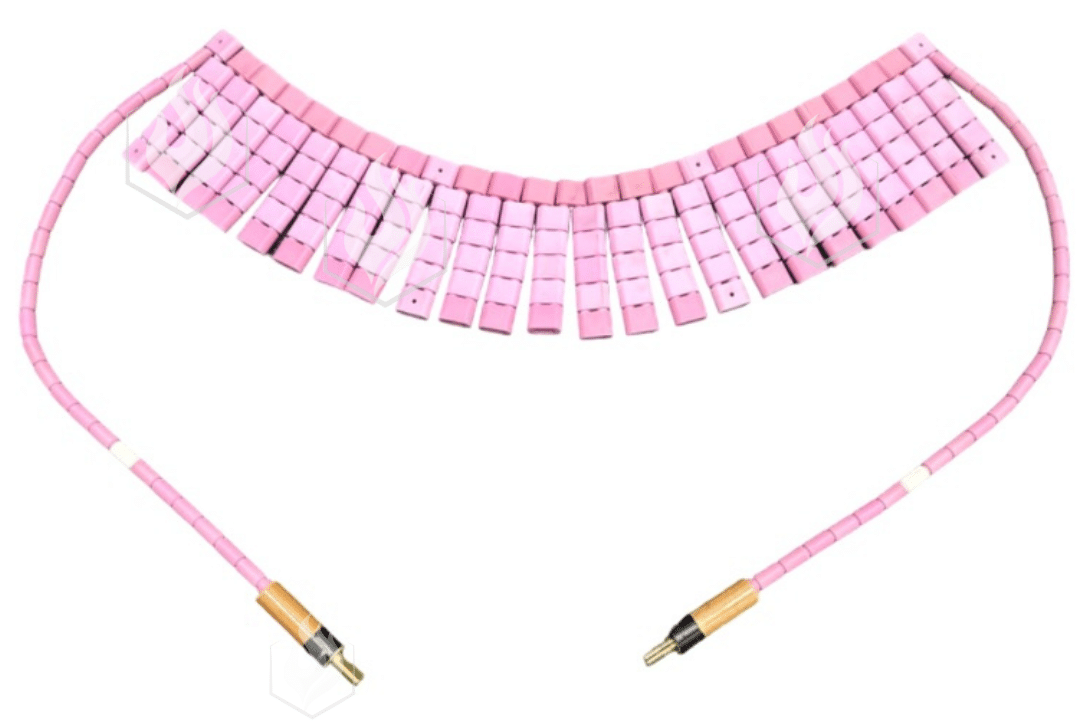

Advanced heating products like TWIN HEAT MODULES, FINGER HEATERS, COIL HEATERS, COOPER KNIT MATS, and FIXED Thermocouple Attachments ensured an efficient, accurate process.

This minimized repair downtime, extended the roller’s lifespan, and ensured performance in high-pressure, high-temperature environments across industries such as:

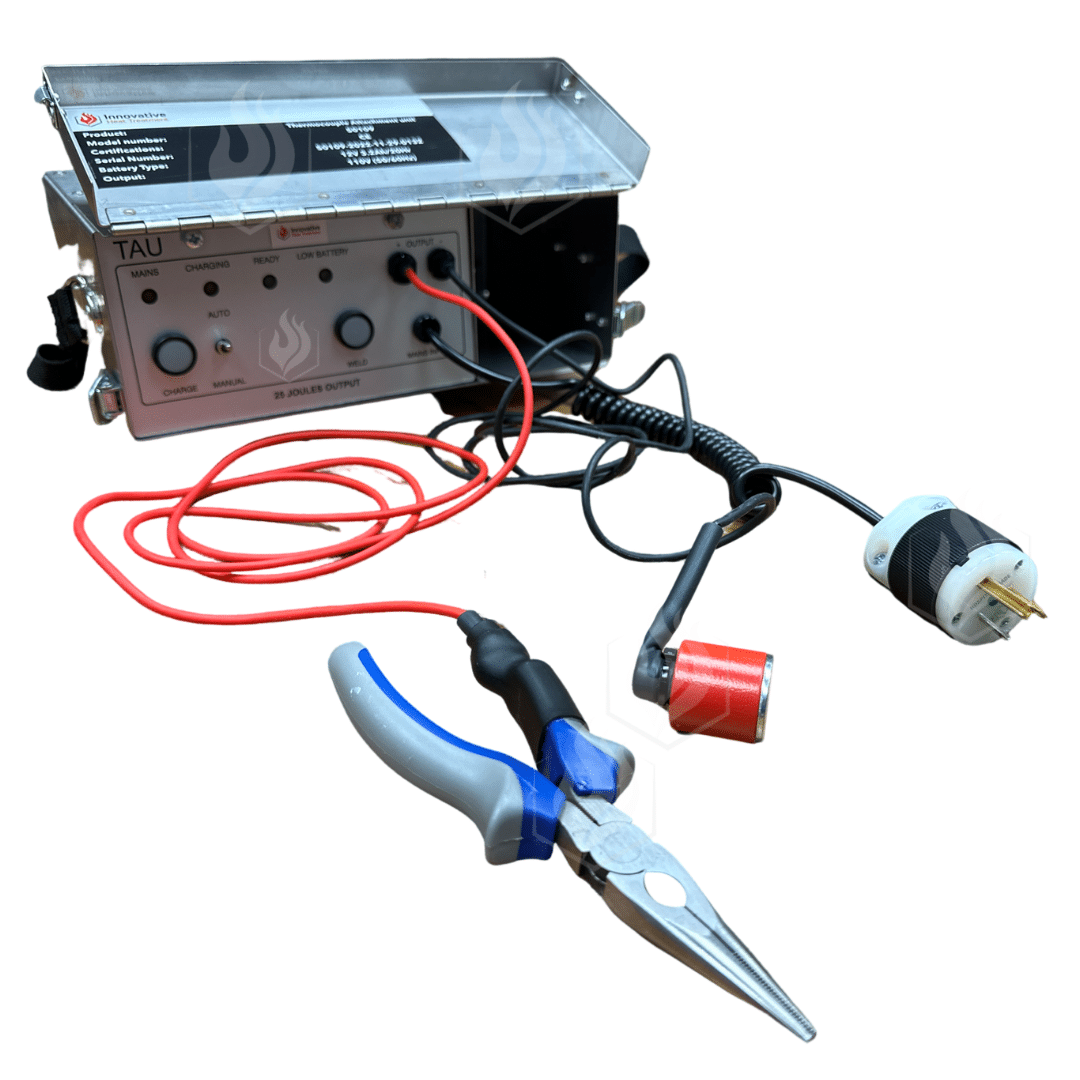

Eurotherm Controlers are powered by 110 VAC.

Twin Heat Module Powered by Welding machine (minimum 300 Amps , 90

percent duty cycle )

See diagram of Twin Heat Module – Setup.