X

- No products in the list

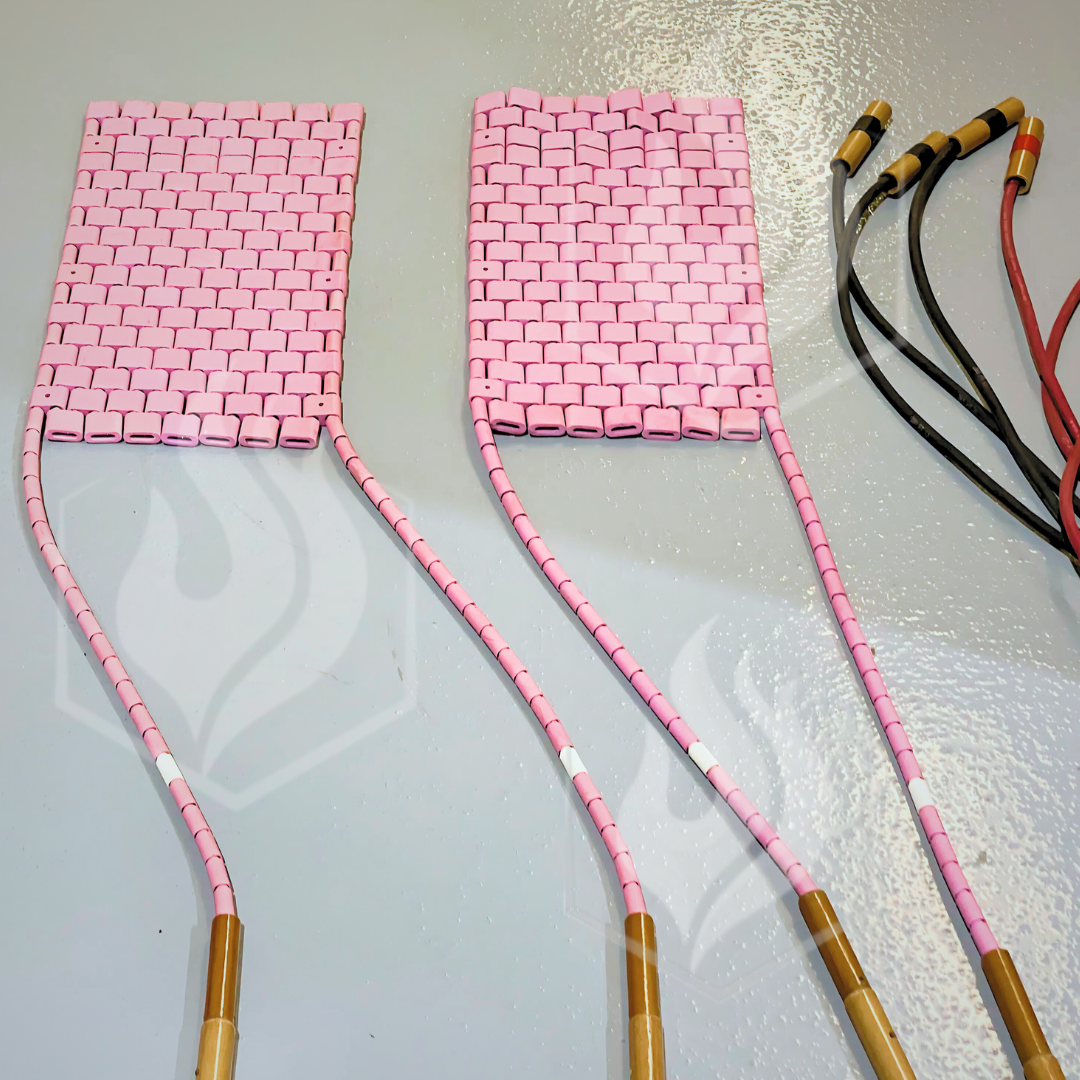

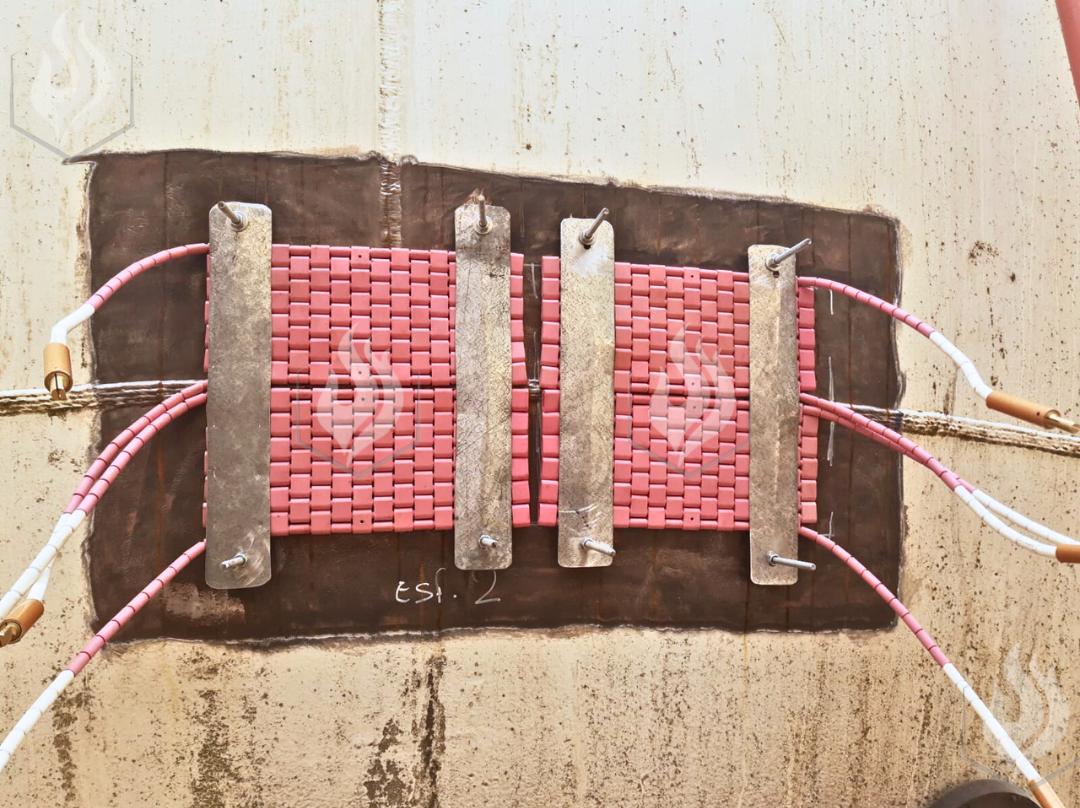

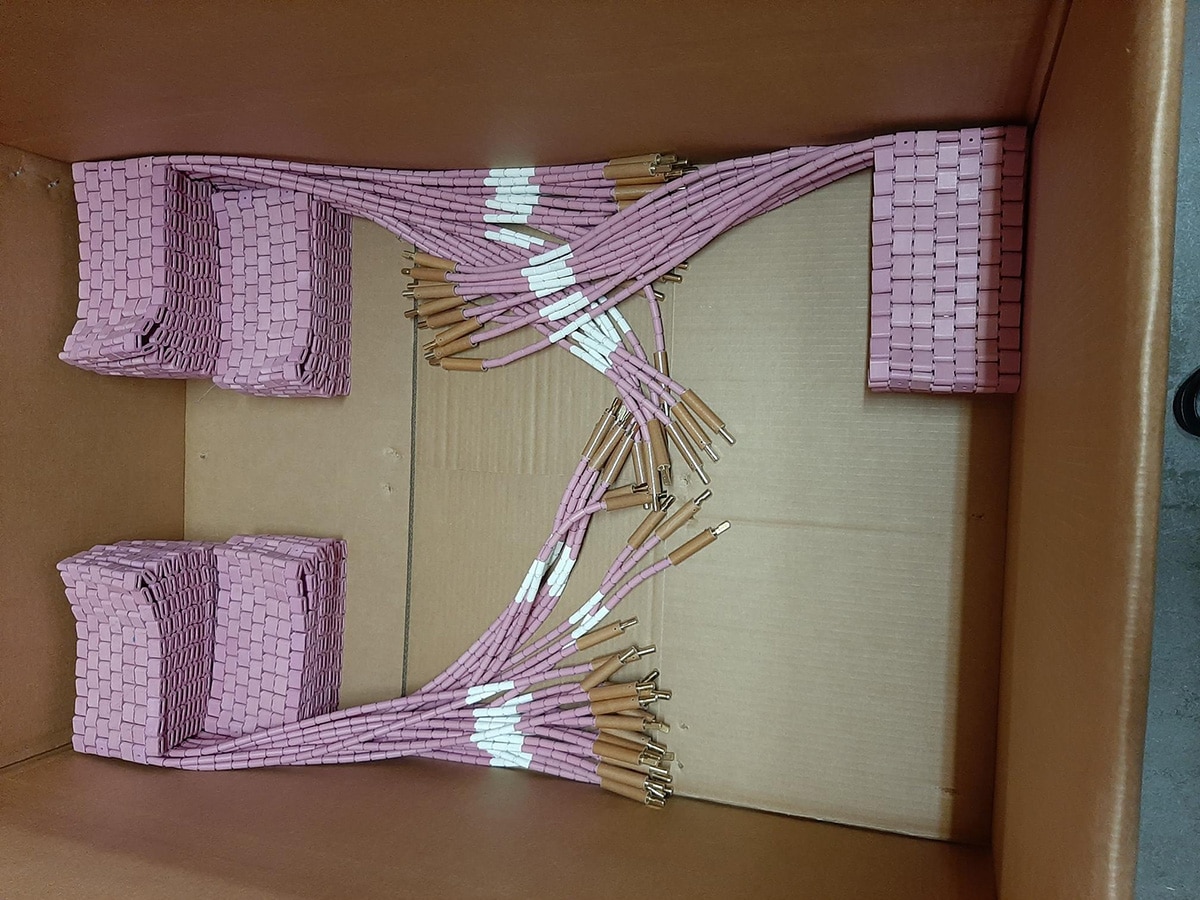

Thanks to their flexibility, FCPs can be applied to both flat and curved surfaces, making them perfect for pre-heating and post-weld heat treatment (PWHT) of pipework butt welds.

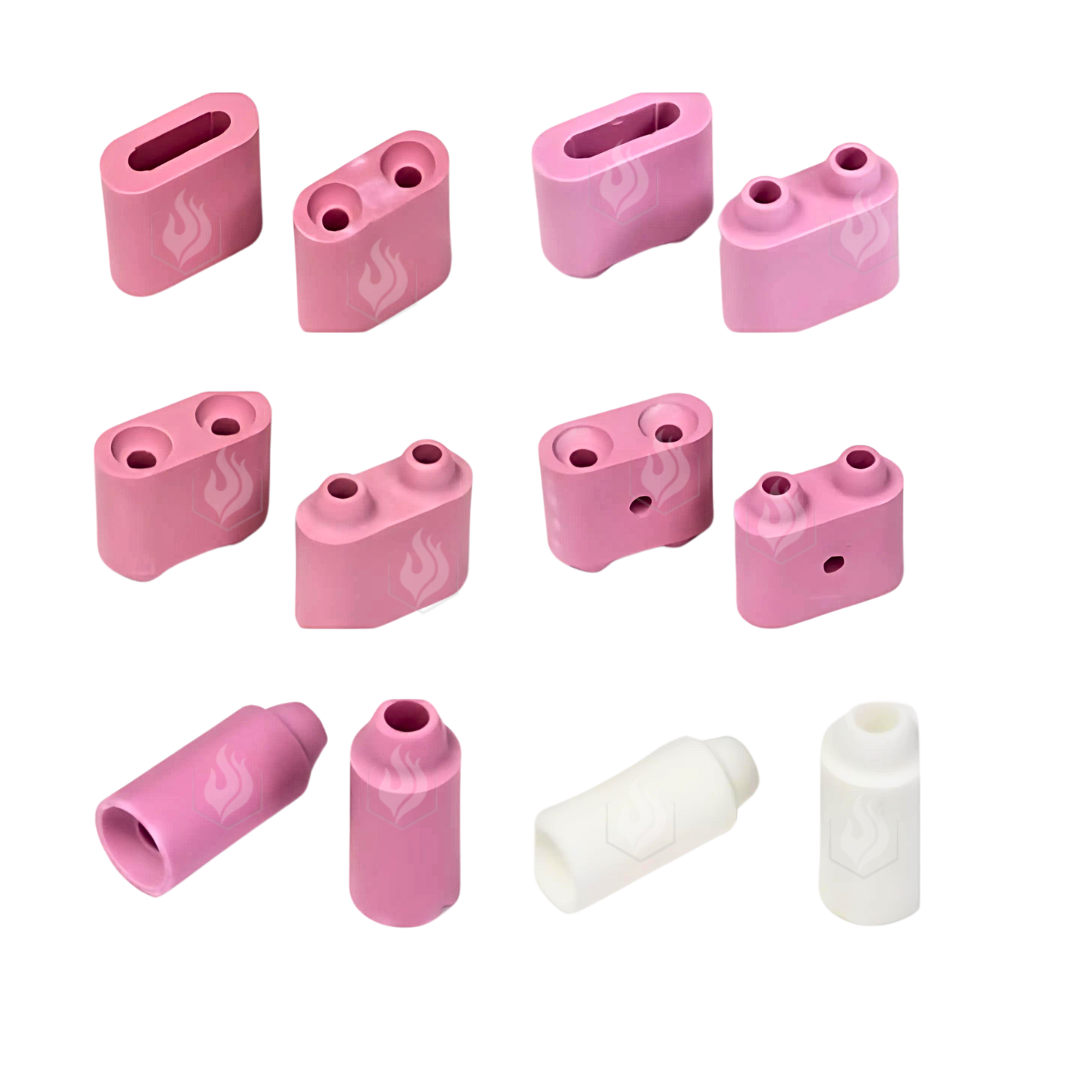

Their modular design ensures adaptability, allowing them to be used across a variety of sizes and shapes.

The Ceramic Pad is manufactured from high alumina ceramic beads with a 60:16 nickle-chromium flexible core wire serpentined within the bead. Nickle tails are weld to the core wire.

The pads are flexible and suitable for heat treatment temperatures up to 1050°C. Temperatures above this value can be the variation of the composition of the core wire.

Highest quality materials available in the construction of our Ceramic Pad (FCP) heating elements.

Flexible ceramic heating elements are butt-welded to cold tails, eliminating junction failures common with lower-quality heaters.

They fit any pipe size or configuration, providing the precise heat required for successful weld treatment.

Available in various power ratings and standard voltages, FCP elements can be customized to your exact needs. When handled properly, they can be reused about 50 times at temperatures up to 1050°C (1922°F). We also offer elements for continuous use at temperatures up to 1200°C.

Preheat is a term associated with the application of heat to metal component prior to and during welding. Mainily Pre-heat treatment of butt welds .

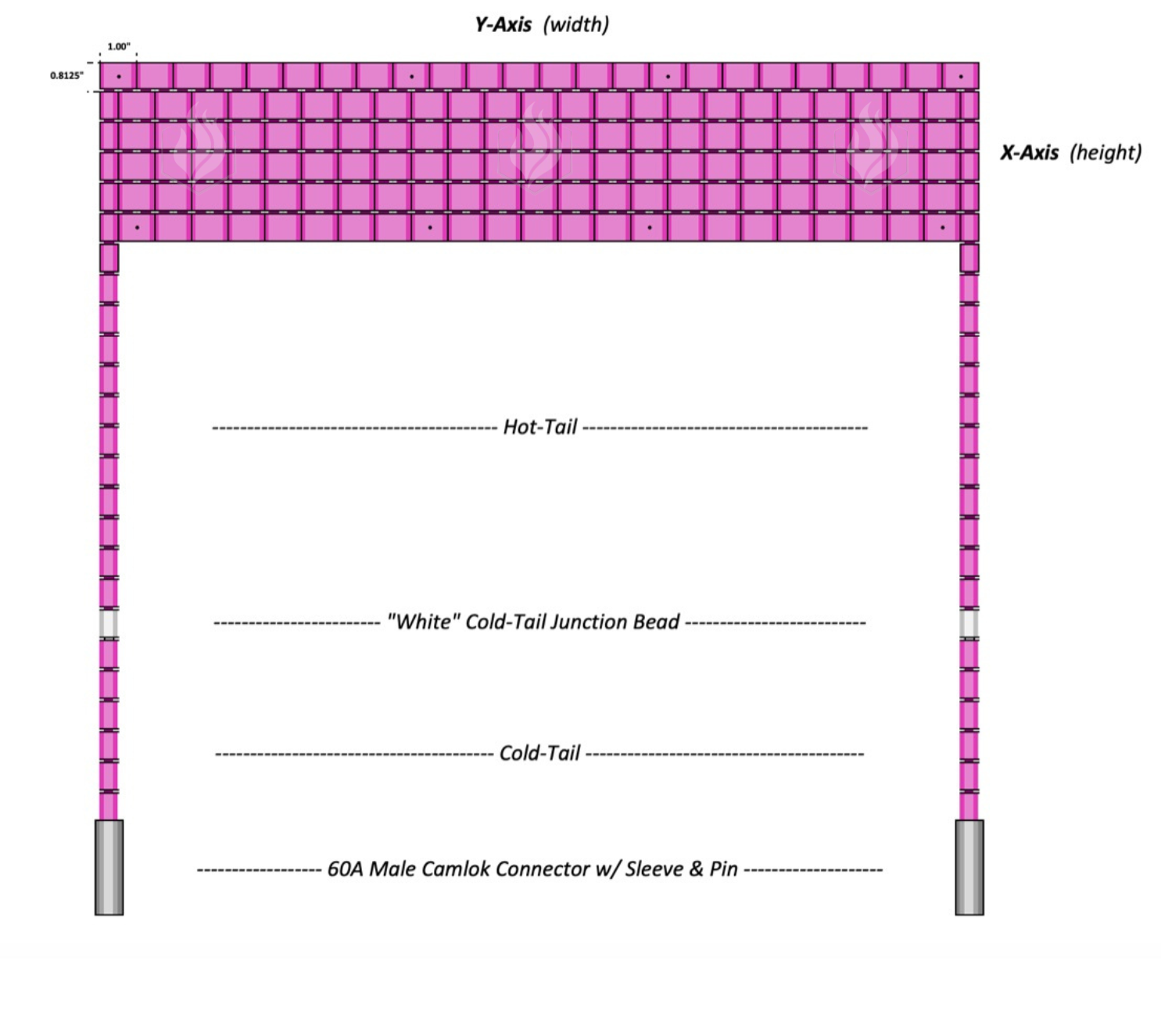

| STOCK REF. | 26603 |

| X. WIDTH. MM | 76 (3") |

| Y. LENGTH. MM | 672 (26.4") |

| VOLTS | 60 |

| kW | 2.7 |

| AMP | 45 |

| STOCK REF. | 26604 |

| X. WIDTH. MM | 102(4") |

| Y. LENGTH. MM | 504(19.8") |

| VOLTS | 60 |

| kW | 2.7 |

| AMP | 45 |

| STOCK REF. | 26606 |

| X. WIDTH. MM | 152 (6") |

| Y. LENGTH. MM | 336 (13.2") |

| VOLTS | 60 |

| kW | 2.7 |

| AMP | 45 |

| STOCK REF. | 26608 |

| X. WIDTH. MM | 203 (8") |

| Y. LENGTH. MM | 252 (10") |

| VOLTS | 60 |

| kW | 2.7 |

| AMP | 45 |

| STOCK REF. | 26610 |

| X. WIDTH. MM | 254 (10") |

| Y. LENGTH. MM | 210 (8.2") |

| VOLTS | 60 |

| kW | 2.7 |

| AMP | 45 |

| STOCK REF. | 26612 |

| X. WIDTH. MM | 305 (12") |

| Y. LENGTH. MM | 168 (6.6") |

| VOLTS | 60 |

| kW | 2.7 |

| AMP | 45 |

| STOCK REF. | 26615 |

| X. WIDTH. MM | 381 (15") |

| Y. LENGTH. MM | 147 (5.7") |

| VOLTS | 60 |

| kW | 2.7 |

| AMP | 45 |

| STOCK REF. | 26616 |

| X. WIDTH. MM | 406 (16") |

| Y. LENGTH. MM | 126 (5") |

| VOLTS | 60 |

| kW | 2.7 |

| AMP | 45 |

| STOCK REF. | 26621 |

| X. WIDTH. MM | 534 (21") |

| Y. LENGTH. MM | 104 (4") |

| VOLTS | 60 |

| kW | 2.7 |

| AMP | 45 |

| STOCK REF. | 26624 |

| X. WIDTH. MM | 610 (24") |

| Y. LENGTH. MM | 84 (3.3") |

| VOLTS | 60 |

| kW | 2.7 |

| AMP | 45 |

| STOCK REF. | 26648 |

| X. WIDTH. MM | 1220 (48") |

| Y. LENGTH. MM | 42 (1.6") |

| VOLTS | 60 |

| kW | 2.7 |

| AMP | 45 |

For paid selection you need to calculate the effective circumference of a pipe FCP

(Flexible ceramic pads) applied.

Formula:

(Outside Diameter of pipe + 10mm*3.142)

Example Formula : Circumference=(184.15mm+10mm)*3.142=610mm

Example Pad code: 26624

610mm(X-aixs)

We recommend: CP24

Gap between flexible ceramic pads(FCP)is limited by wall thickness(WT).Standard is 50mm(1.97″) this would be maximum.

Thickness recommended 1″ thick(25mm). this prevents heat lost from the heat treatment process.

We recommend 8 ibs density (128kg/m3) of silica fibre.

Why it has no VOC and can be reused 30 to 40 times for pre heating applications

Multiply Celsius value by 1.8 and then add 32.

Example : 600 C what’s is this in Fahrenheit

( 600 X 1.8 ). + 32 = 1112 F

Deduct 32 from Fahrenheit and then divide by 1.8

Example : 1112 Fahrenheit what’s is this in Celsius

( 1112 X- 32 ) / 1.8 = 600 C

Multiply kw value by 3412.142

Example : 50 kW Convert to BTU

( 50 kW X 3412.142 ) = 170,607.1 BTU/HR

Divide BTU by kW

Example : (6,000,000 BTU / hr ) Convert to kW

(6,000,000 BTU / hr ) / 3412.142 =m1758.48 kW

What spacing or gap is recommended that we should have between

pads on the Heat Treatment material ?

> Gap between flexible ceramic pads ( FCP) is limited by wall thickness

> (WT). Standard is 50 mm ( 1.97″) this would be maximum.

Thickness recommended 1″ Thick ( 25 mm ). This prevents heat lost from the heat treatment process.

We recommend 8 lbs density ( 128 kg/m3) of silica fibre. Why it has no VOC and Can be reused 30 to 40 times for pre-heating applications.

Leave the application on our website or by phone

The manager will contact you for further details

We will gladly deliver your order soon