X

- No products in the list

Innovative Heat Treatment – MINI WELD -THERMOCOUPLE ATTATCHMENT UNIT

Discover a design so remarkably compact and astonishingly light it will take your project beyond this world!

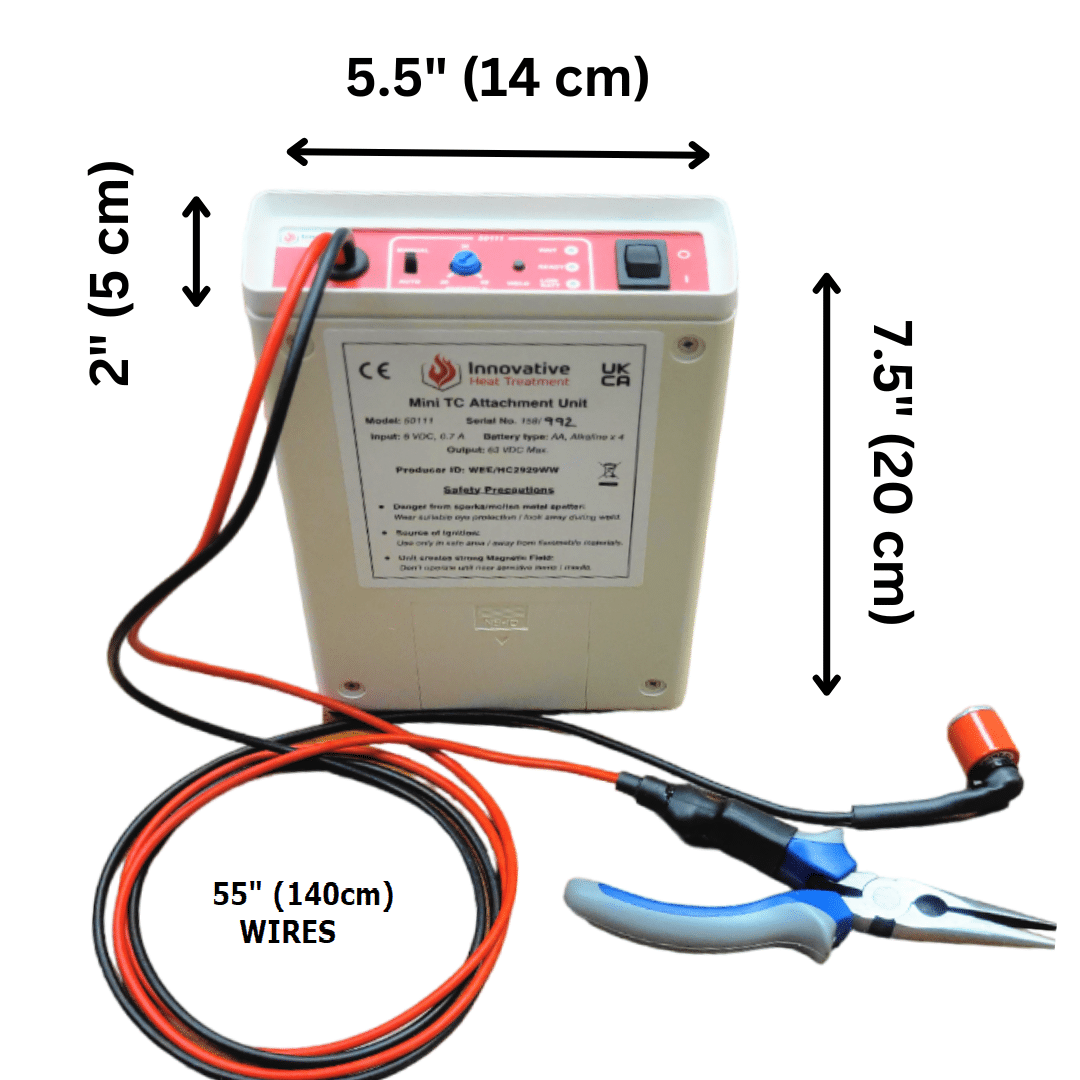

The MINI WELD is a capacitance-discharge welding unit used for the attachment of thermocouple wires to a work piece. It is a more compact alternative to larger, heavier units but has the same energy output.

Three )3) Standaard settiings : 1) 20 Joules 2) 30 Joules 3) 50 Joules

Both Manual and Automatic Settings.

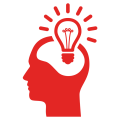

Size: 137mm wide x 190mm long x 45 height (Excluding leads and carry case)

Weight: 1.2 kilos (Including batteries, leads and carry case)

Battery Type: 4 x AA cell (Alkaline 1.5V recommended for best performance)

Weld Voltage: 37 to 60V (20 to 50 joules output)

Charging Time: Approx. 15 seconds at 30 joules

Battery life: Approx. 300 welds at 30 joules (Fresh batteries)

EMC: EN61000-6-1:2001, EN61000-6-3:2001

LVD: EN61010-1:2001

| Size: |

Width X Length X Height 137 mm X 190 mm X 45 mm 5.5 " X 7.5 " X 2 “ (Excluding leads and carry case) |

|

| Weight: |

1.2 Kilos 2.5 lbs (Includes Batteries, leads & carrying case) |

|

| Battery: | 4. X AA Cell ( Alkaline 1.5 V) | |

| Weld Voltage: | 1. 20 Joule. 2. 30 Joule 3. 50 Joule | |

| Charging time: | Approximately 15 seconds at 30 Joule | |

| Battery Life: | Approximately 300 welds at 30 Joules | |

| EMC: | EN61000-6-1:2001. EN61000-6-3:2001 | |

| LVD: | EN61000-1:2001 | |

| CATALOG # | 50111 |

| CERTIFICATIONS # | CSA, ETL, CE, ISO:9001 |

| DIMENSIONS # |

137 mm (L) X 190 mm (W) X 45 mm (H) 7.5 " (L) X 5.5 " (W) X 2 " (H) |

| WEIGHT | 1.74 kgs or 2.5lbs |

| Weight | 1.74kg (INCLUDES BATTERIES & CASE) |

| Max operating voltage | 100V |

| Charge time | 15 seconds at 30 joules |

| Discharge energy | 20-50 Joules -37 to 60 volts |

| T/couple types | Type K |

| Standard Wire size | 0.711mm dia |

| Approx no of applications before re-charge | 250 |

| Battery | 4 x AA alkaline batteries, with a |

FRONT PANEL CONTROLS

Mini-Weld Thermocouple Attachment Unit provides a reliable and extremely accurate method of temperature measurement of pre and post weld heat treatment processes by the direct attachment of thermocouples to the workpiece known as the capacitive discharge method.

Accurate temperature measurement is ensured by the attachment of thermocouple conductor wires directly to the metal surface by a spark discharge welding system. Accordingly, the metal surface becomes the hot junction of the thermocouple, so eliminating any inaccuracy associated with direct heat transfer from the heating source. After the wires are removed from the metal surface, it is usually necessary only to lightly dress the local area.

The Mini welding unit is significantly lighter and smaller than the standard unit and therefore is more portable. The unit is therefore particularly useful in locations where access is poor.

Applications

Variable, operator selectable 20 to 50 Joules energy output suitable for attaching various sizes of thermocouple wire. With its optional manual or automatic operating mode, it is ideal for attaching thermocouples on difficult to reach areas of the workpiece and where for

A compact, and lightweight portable unit. Powered by (4) four, 1.5V, AA batteries the unit uses the capacitancedischarge method for the attachment of a thermocouple wire to a workpiece, to allow temperature recording and control instruments to accurately read the temperature of the workpiece being heat treated.

INSTRUMENT CARE

Ensure batteries are fitted correctly according to polarity markings on compartment.

Internal damage may result from wrong fitting.

The TW158 unit is NOT waterproof so avoid water ingress to front panel.

Clean unit using slightly damp cloth or, for tough stains, use cloth impregnated with WD40 cleaner.

SAFETY PRECAUTIONS

Eye protection is recommended to guard against molten metal spatter when weld occurs.

The weld spark could be a source of ignition for flammable liquids or gases so ensure the TW158 is

only used in safe areas.

Avoid looking directly at bright spark when making the welded joint.

Ensure the thermocouple wire is not connected to any control equipment as these might be damaged

during energy discharge.

KEY POINTS:

| Catalog # | Description: | |

|---|---|---|

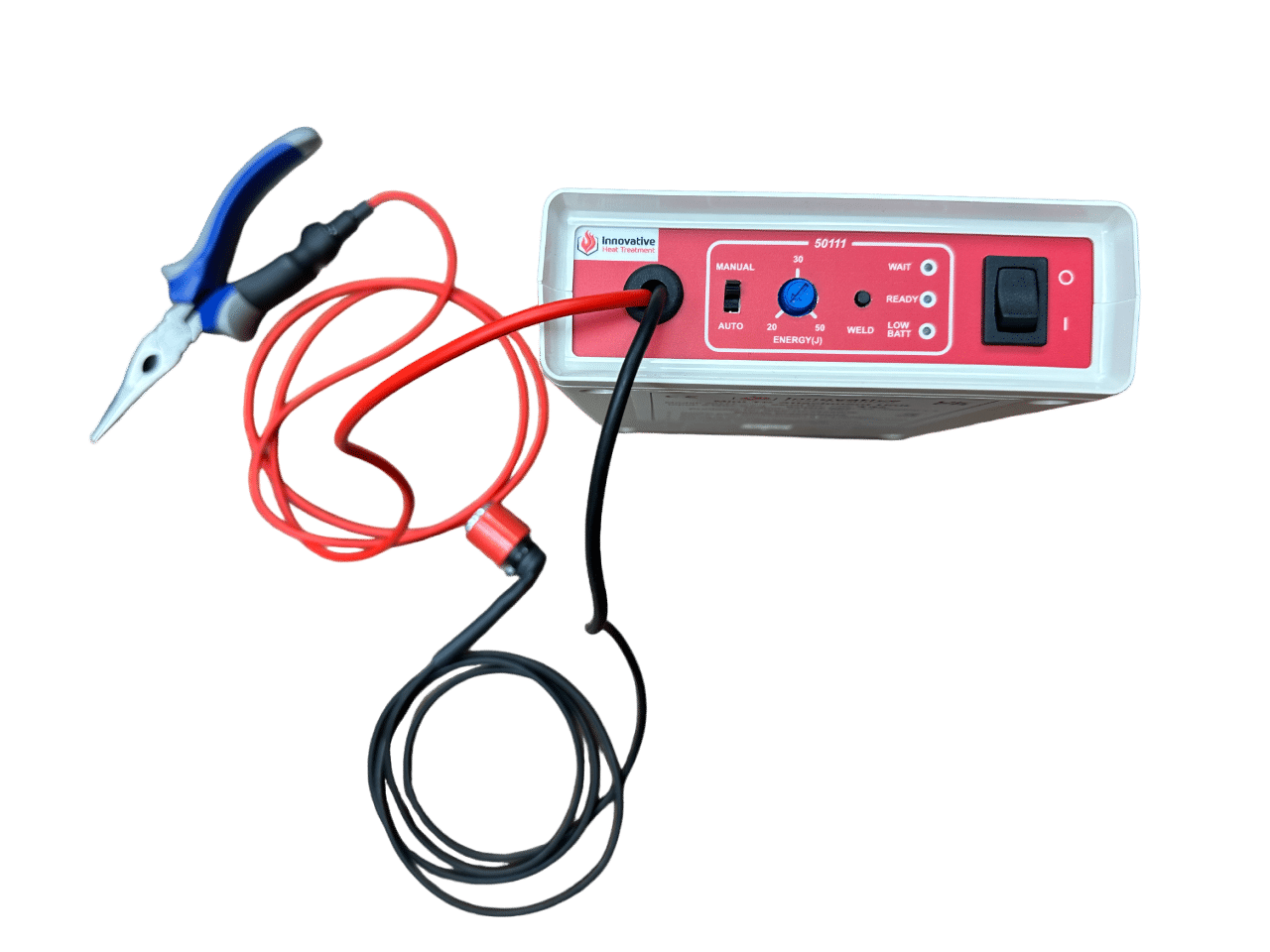

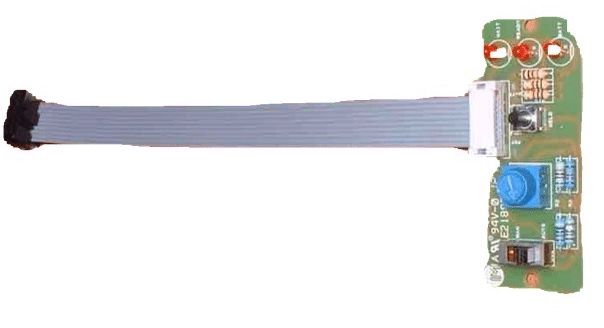

| 50125 | MINI-WELD MOTHERBOARD CONTROL BOARD | |

| 50126 | MINI-WELD LED SWITCH | |

| 50127 | MINI-WELD PLIERS | |

| 50128 | MINI-WELD MAGNET | |

| 50129 | MINI-WELD PROTECTIVE CASE WITH CARRYING STRAP |

| Catalog # | Description: | ||

|---|---|---|---|

|

50125 | MINI-WELD MOTHERBOARD CONTROL BOARD | |

| 50126 | MINI-WELD LED SWITCH | ||

|

50127 | MINI-WELD PLIERS | |

|

50128 | MINI-WELD MAGNET | |

|

50129 | MINI-WELD PROTECTIVE CASE WITH CARRYING STRAP | |

|

50158 | MINI-WELD: FRONT PANEL LED PCB BOARD |

| CYCLE TIME | Approximately 15 seconds per weld at 30 joules |

| ENDURANCE | Approximately 250 welds at 30 joules from new batteries |

| PROTECTION | IP30. The mini-weld is not waterproof and should be protected in wet conditions |

| SAFETY | BSEN 1010-1:1983 |

| EMC |

BSEN 50081-1:1992 BSEN 50082-1:1998

EMC: EN61000-6-1:2001, EN61000-6-3:2001 LVD: EN61010-1:2001 Product is WEEE compliant |

REMEMBER THAT THIS IS A PIECE OF ELECTRICAL EQUIPMENT AND IT SHOULD BE TREATED WITH THE RESPECT THAT ELECTRICAL UNITS DESERVE. NORMAL ELECTRICAL SAFETY STANDARDS APPLY.

Leave the application on our website or by phone

The manager will contact you for further details

We will gladly deliver your order soon