X

- No products in the list

This case study examines a breakthrough in steel fabrication: a more efficient method that replaces traditional Pre-Heat & Post-weld heat treating methods with a more precise heat control system. This innovation maintains consistent heat, boosts structural integrity, and protects the workpiece from damage.

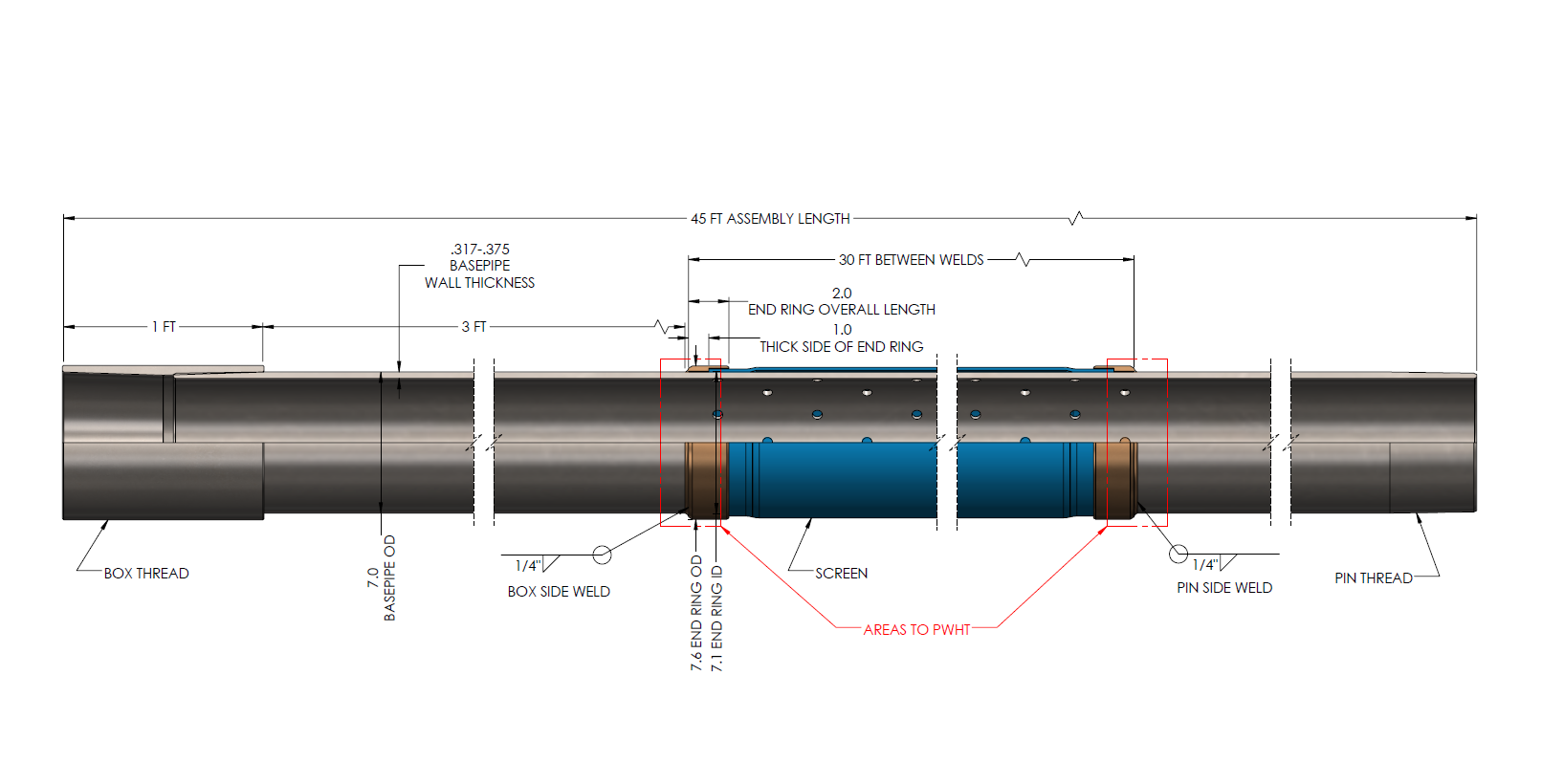

The client plans to perform pre-heat treatment on two separate sections of a steel workpiece, positioned 30 feet apart, ensuring the temperature remains consistent throughout.

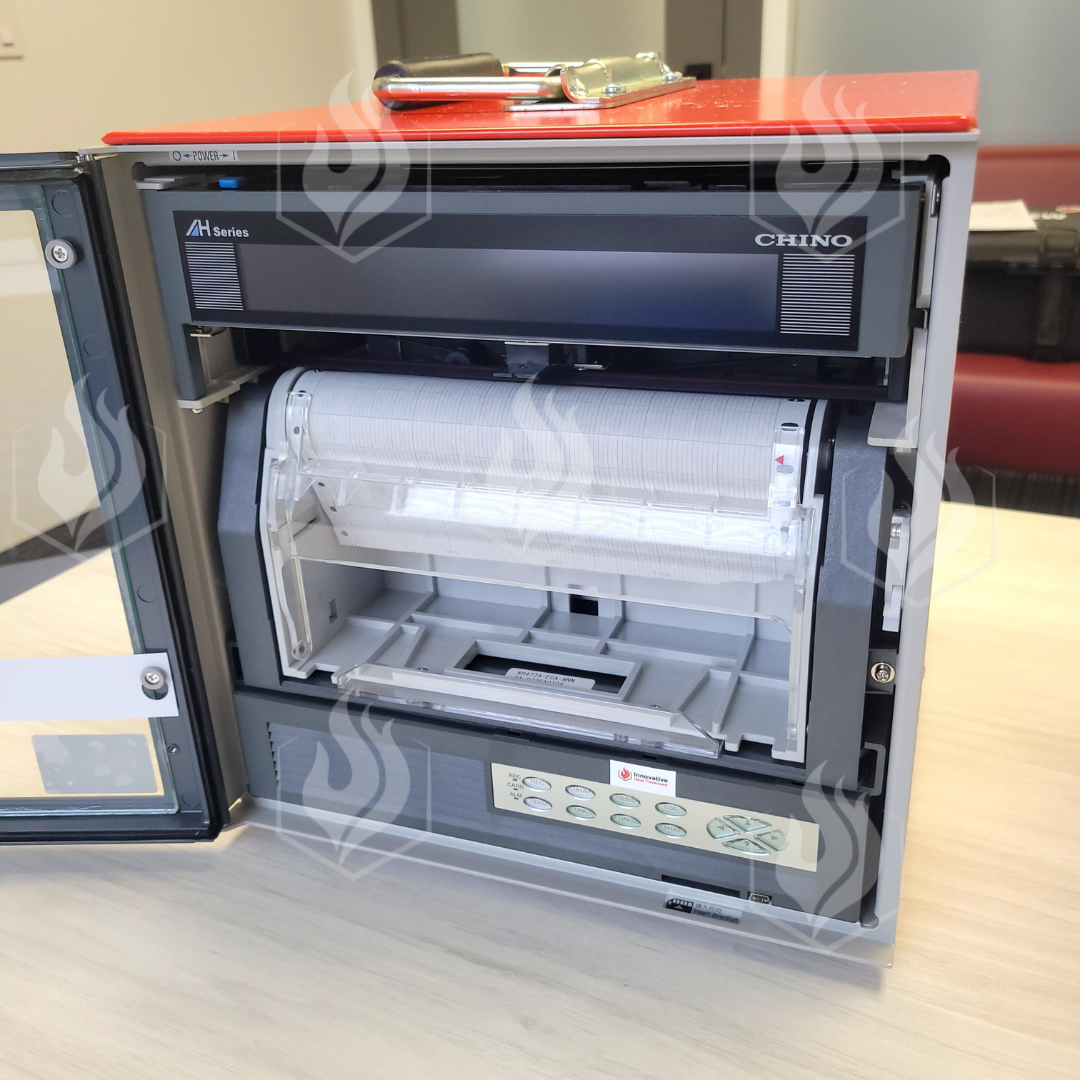

Documenting the heat treatment process is essential for quality assurance and quality control records (QAQC).

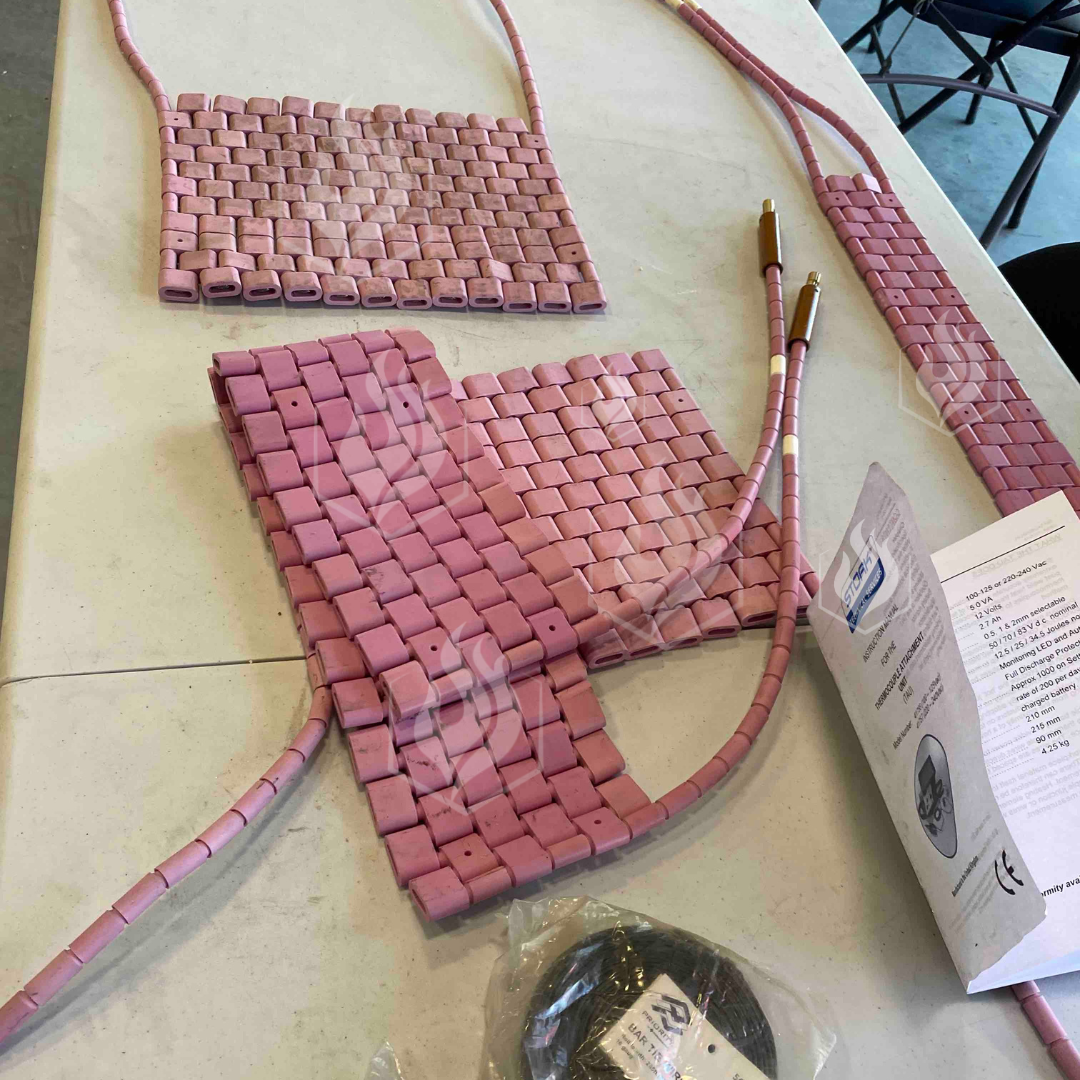

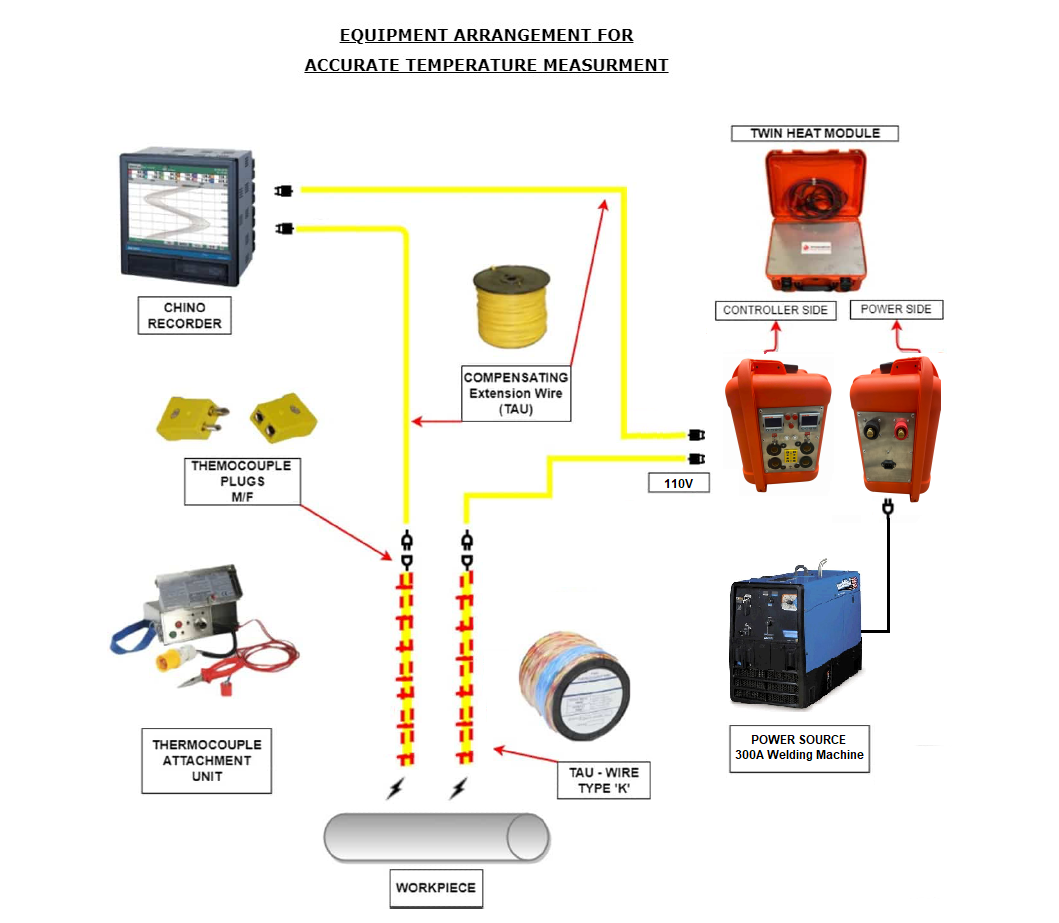

In order to address the challenge presented, we reccomended the following product solutions;

The clients approach involved a sequence of carefully planned steps:

Flexible Ceramic Pads and a Twin Heat Module for pre-heat treatment enabled simultaneous heat treatment across the two separate areas.

This method ensured consistent temperature maintenance throughout the pre-heat and post-weld process.

Temperature recordings were done by the Chino Paper & Digital Recorder for QAQC purposes.

The pre-heat treatment not only enhanced the structural integrity of the steel workpiece but also streamlined the process.

The four built-in, high-strength limpet magnets are rated to withstand

temperatures up to 250°C (482°F) with a 35 lb pull. The magnets will begin to lose

magnetic pull at this temperature. If you require stronger magnets, please

consider our pro-series magnetic pads designed for Post Weld Heat Treatment

(PWHT).

These are designed for Post Weld Heat Treatment (PWHT)

https://innovativeheattreatment.com/product/proseries-magnetic-ceramic-

heating-pads/

Yes, you can. Normally, there is 2”-4” spacing between the flexible ceramic pad

and the insulation. We can adjust the insulation length or add to it based on your

requirements.

Repair teams report a saving of about 60 % of the setup ups time.

Yes, we offer technician-led on-site training for your team. Additionally, we provide

competitive online training covering maintenance and standard operating

procedures for the equipment.