X

- No products in the list

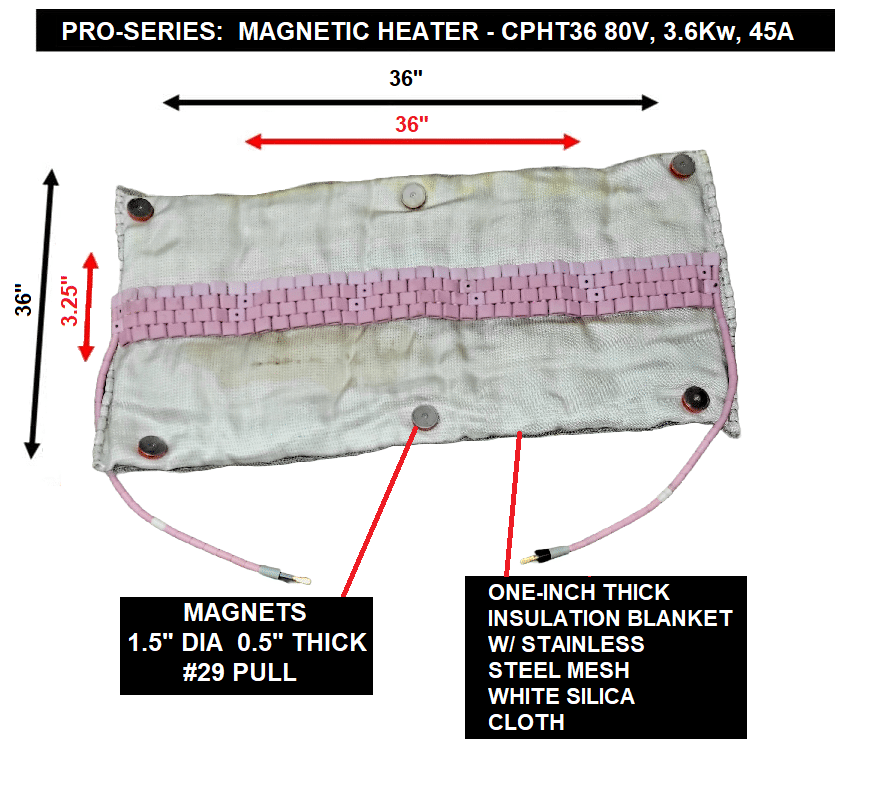

PRO-SERIES HIGH TEMPERATURE (1100 F) MAGNETIC CERAMIC PADS.

Specifically designed to REDUCE SETUP TIME for the Heat Treatment process.

Applications used for Pre-heating welded joints for prior to and during the welding Process.

Pro-series High Temperature Magnetic Pads are assembled from a ceramic pad heater attached to silica fibre meshed mat as a standard. Stainless steel backing is an option.

Key feature is the standard High Temperature – Magnetic ceramic Pads will BEND both ways To fit concave and convex fabrications.

CORE WIRE : 80: 20 NICKLE CHROME

VOLTAGE : 80 V

CURRENT : 45 A

POWER. : 3.6 Kw

Includes 4-6 built in HIGH STRENGTH MAGNETS.

PRODUCT DESCRIPTIONS:

HIGH TEMPERATURE- MAGNETIC CERAMIC PADS COME WITH Blanket with Stainless steel mesh white silica cloth. It consists Of one (1) inch insulation.

TEMPERATURE RATING : 1100 F ( 600 C)

MAGNETIC STRENGHT : # 29 PULL MAGNETS

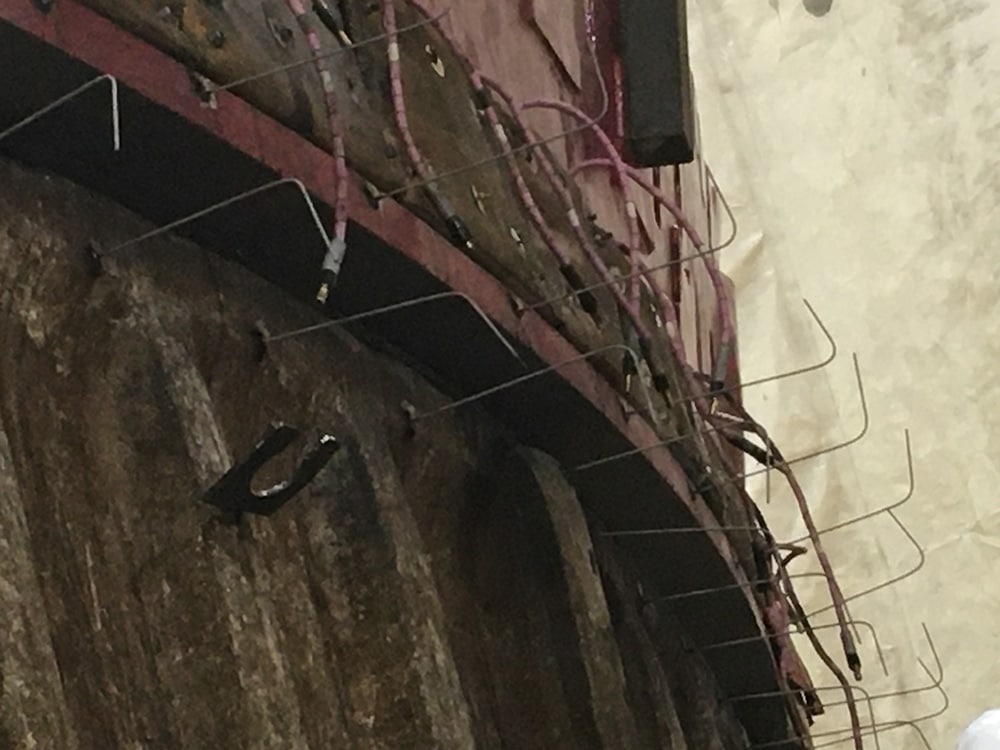

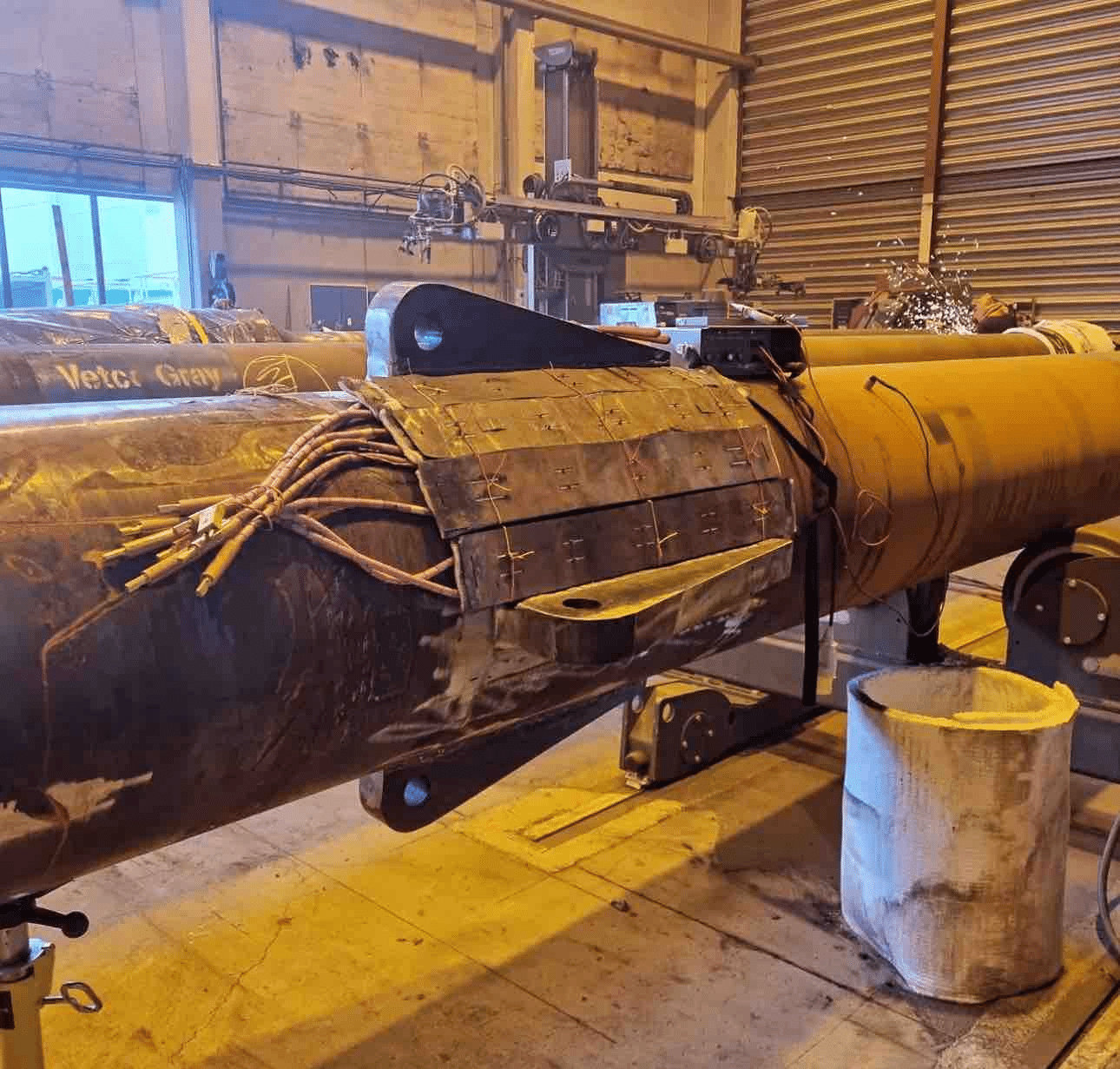

Heat Treatment: MINING EQUIPMENT REPAIR – DIGGER

Innovative Heat Treatment Magnetic – Flexible ceremic pad heaters are manufactured using high grade nickel chrome (NiCr) 80/20 19 strand wire,and insulated using sintered alumina oxide beads, giving flexibility and increased high heat transfer capability.

Designed for pre and post weld heat treatments, our range of ceramic pad heatres will function efficiently whether they are used as a curved or flat application, and are available in an extensive list of sizes with voltages.

Most standard sizes are available to order ex stock, however, non standard sizes can be manufactured to your requirments quickly, and, should you require any special heating configuration ,voltage or power rating, we can provide you with a heating element custom built to meet your exact needs.

The design of this Magnetic Pads has several advantages to the standard ceramic heater.

Ideal for repair of Mining Equipment .

TRAINING – MINING EQUIPMENT REPAIR – TWIN HEAT MODULE AND MAGNETIC PADS

TRAINING – MINING EQUIPMENT REPAIR – TWIN HEAT MODULE AND MAGNETIC PADS

REPAIR OF SHOVEL – MAGNETIC PADS SAVED 64 % SETUP TIME AND REDUCED LABOR COST

| CATALOG # | CPHT3 |

| REFERENCE | 20403-HT |

| VOLTAGE | 80 |

| KW | 3.6 |

| AMP | 45V |

| DIMENSIONS HEATER | 3" x 40" |

| WIRE | 80:20 NI CHROME WIRE |

| Dimensions Insulation | 9" x 45" |

| | |

| CATALOG # | CPHT4 |

| REFERENCE | 20404-HT |

| VOLTAGE | 80 |

| KW | 3.6 |

| AMP | 45V |

| DIMENSIONS HEATER | 4" x 29" |

| WIRE | 80:20 NI CHROME WIRE |

| Dimensions Insulation | 12" x 34" |

| | |

| CATALOG # | CPHT5 |

| REFERENCE | 20405-HT |

| VOLTAGE | 80 |

| KW | 3.6 |

| AMP | 45V |

| DIMENSIONS HEATER | 5" x 24" |

| WIRE | 80:20 NI CHROME WIRE |

| Dimensions Insulation | 912" x 29" |

| | |

| CATALOG # | CPHT6 |

| REFERENCE | 20406 |

| VOLTAGE | 80 |

| KW | 3.6 |

| AMP | 45V |

| DIMENSIONS HEATER | 6" x 19.5" |

| WIRE | 80:20 NI CHROME WIRE |

| Dimensions Insulation | 12" x 24" |

| | |

| CATALOG # | CPHT7 |

| REFERENCE | 20407-HT |

| VOLTAGE | 80 |

| KW | 3.6 |

| AMP | 45V |

| DIMENSIONS HEATER | 7" x 17.25" |

| WIRE | 80:20 NI CHROME WIRE |

| Dimensions Insulation | 12" x 24" |

| | |

| CATALOG # | CPHT8 |

| REFERENCE | 20408-HT |

| VOLTAGE | 80 |

| KW | 3.6 |

| AMP | 45V |

| DIMENSIONS HEATER | 8" x 14.5" |

| WIRE | 80:20 NI CHROME WIRE |

| Dimensions Insulation | 12" x 24" |

| | |

| CATALOG # | CPHT10 |

| REFERENCE | 20410-HT |

| VOLTAGE | 80 |

| KW | 3.6 |

| AMP | 45V |

| DIMENSIONS HEATER | 10" x 14.5" |

| WIRE | 80:20 NI CHROME WIRE |

| Dimensions Insulation | 12" x 24" |

| | |

| CATALOG # | CPHT12 |

| REFERENCE | 20412-HT |

| VOLTAGE | 80 |

| KW | 3.6 |

| AMP | 45V |

| DIMENSIONS HEATER | 12" x 9.75" |

| WIRE | 80:20 NI CHROME WIRE |

| Dimensions Insulation | 12" x 24" |

| | |

| CATALOG # | CPHT15 |

| REFERENCE | 20415-HT |

| VOLTAGE | 80 |

| KW | 3.6 |

| AMP | 45V |

| DIMENSIONS HEATER | 15" x 8" |

| WIRE | 80:20 NI CHROME WIRE |

| Dimensions Insulation | 12" x 24" |

| | |

| CATALOG # | CPHT18 |

| REFERENCE | 20418-HT |

| VOLTAGE | 80 |

| KW | 3.6 |

| AMP | 45V |

| DIMENSIONS HEATER | 18" x 6.5" |

| WIRE | 80:20 NI CHROME WIRE |

| Dimensions Insulation | 12" x 24" |

| | |

Leave the application on our website or by phone

The manager will contact you for further details

We will gladly deliver your order soon