Menu

X

- No products in the list

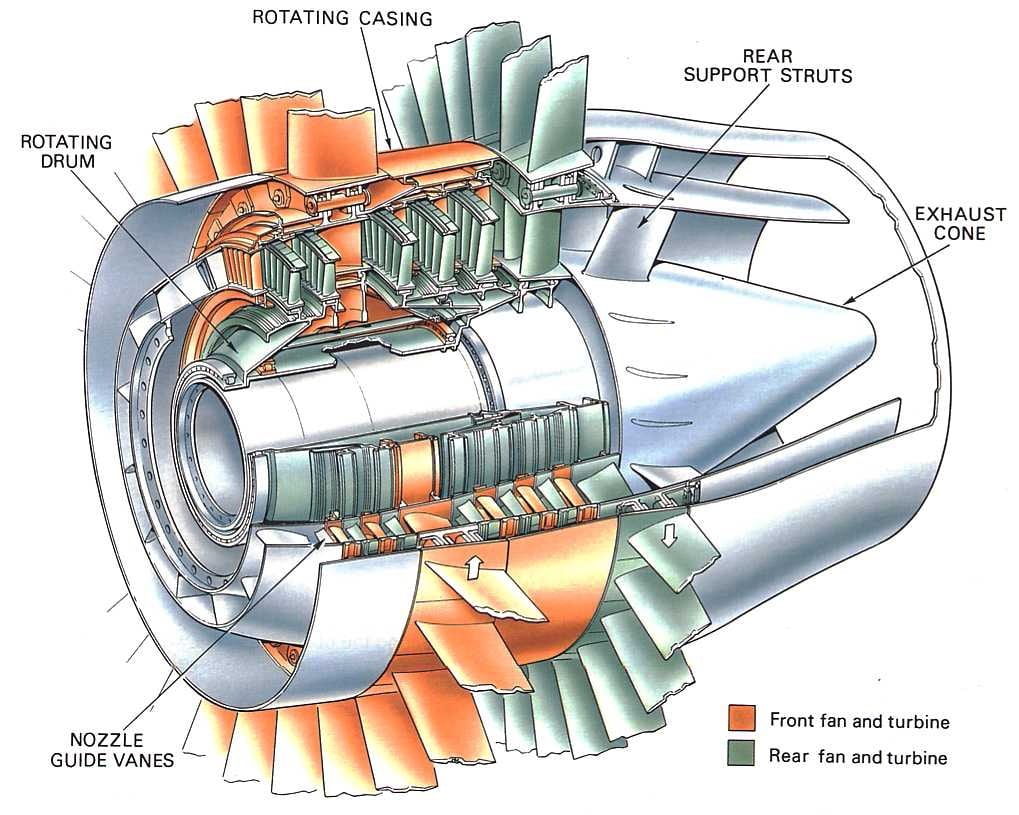

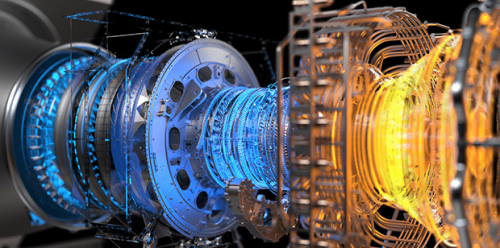

Our case study investigates the effects of unconventional Industrial Stress Relieving Post Weld Heat Treatments (PWHT) on cone-shaped workpieces, demonstrating the benefits achieved with inventive approaches.

FAA-certified repair station specializing in gas turbine engine component repairs for the aviation and aeroderivative industries.

Requesting an onsite solution for localized heat treating with the Operating Temperature: 0°C – 1050 °C.

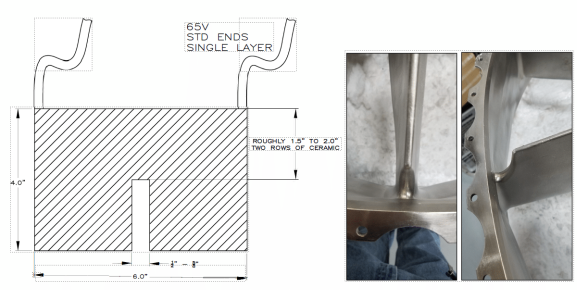

The project requires Electrical Resistance Equipment, including local stress units for our application of heat treating – cone shaped pieces.

Key Issue:

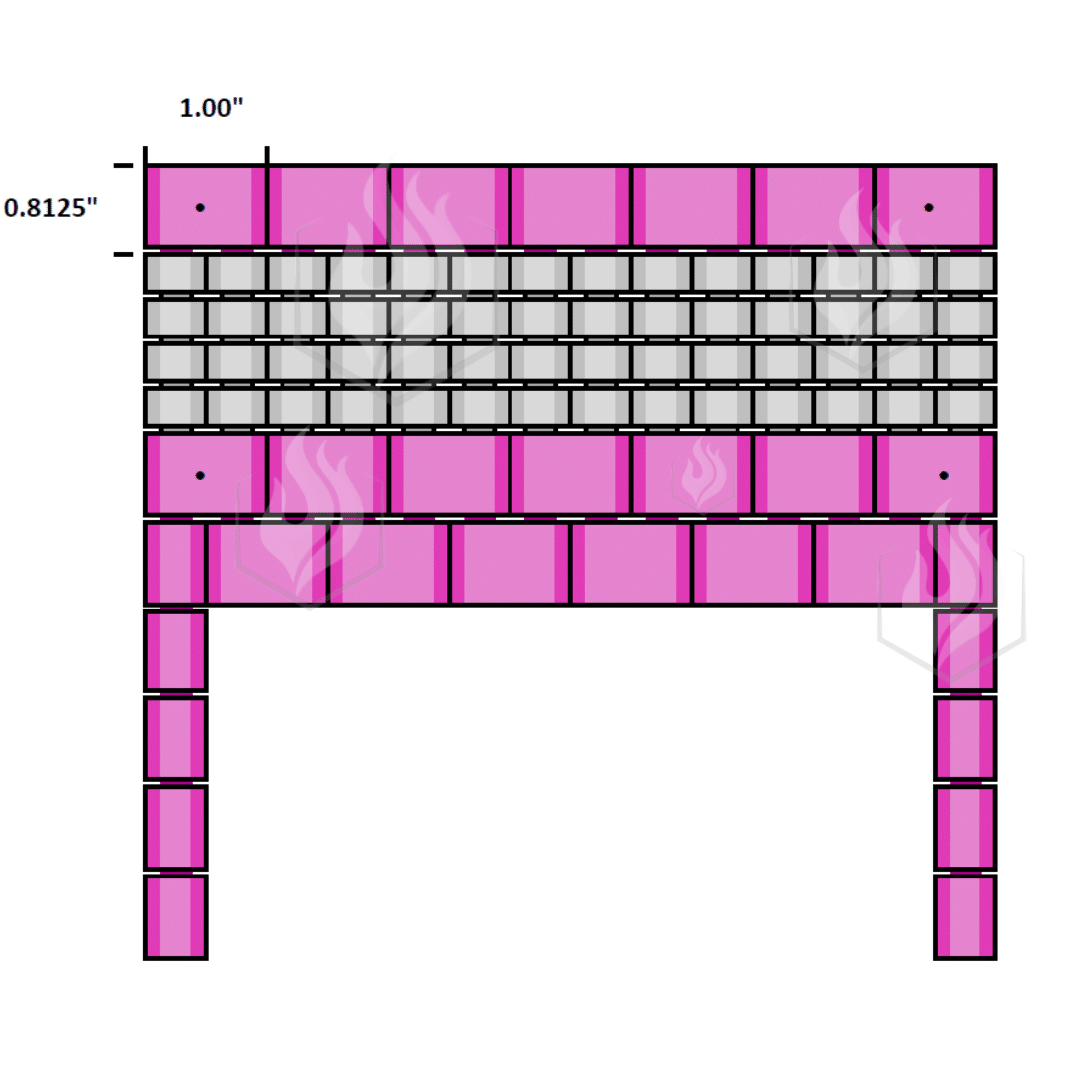

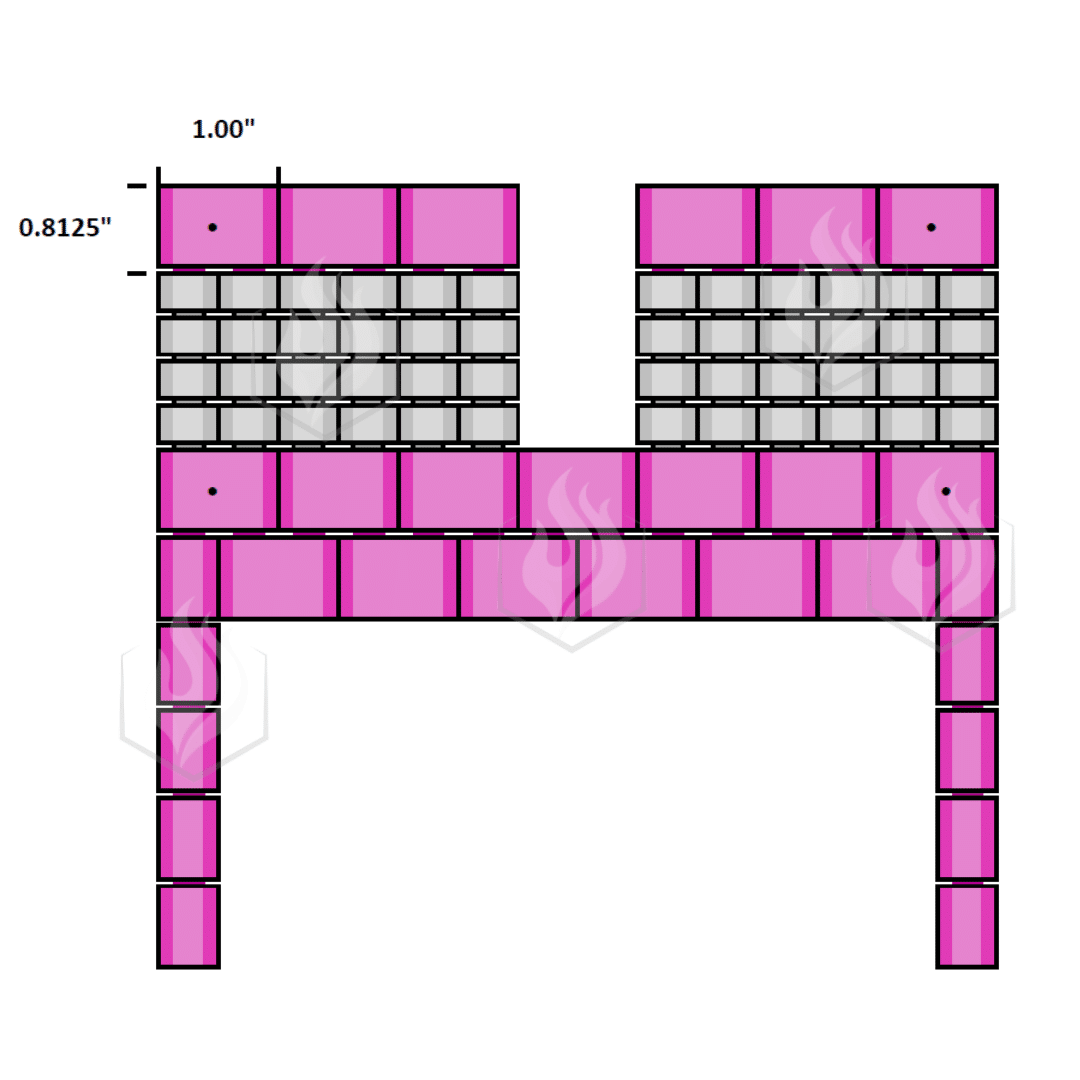

For stress relief in cone-shaped workpieces requiring Electrical Resistance equipment, Finger Ceramic Elements are the recommended choice.

Finger elements are used Pre-Heat Treatment and Post Weld Heat Treatment (PWHT)

The element features dual Nickel Chrome wires in alumina beads for insulation and heat transfer, with a standard maximum temperature of 1050°C, and 1250°C for stainless steel treatment using Anthill wire, ending in steel or twistlock connectors.

The use of Finger Ceramic Elements for the project efficiently relieved stress from cone-shaped metal workpieces, required little maintenance, and withstood high temperatures.

This approach enabled the client to soften materials for pre-weld heat treatment and re-harden them post – weld repair to restore essential properties for service reintegration.

Additionally, the treatment effectively relieved stresses caused by engine operation or repairs and was used to cure various applied coatings.

The four built-in, high-strength limpet magnets are rated to withstand

temperatures up to 250°C (482°F) with a 35 lb pull. The magnets will begin to lose

magnetic pull at this temperature. If you require stronger magnets, please

consider our pro-series magnetic pads designed for Post Weld Heat Treatment

(PWHT).

These are designed for Post Weld Heat Treatment (PWHT)

https://innovativeheattreatment.com/product/proseries-magnetic-ceramic-

heating-pads/

Yes, you can. Normally, there is 2”-4” spacing between the flexible ceramic pad

and the insulation. We can adjust the insulation length or add to it based on your

requirements.

Repair teams report a saving of about 60 % of the setup ups time.

Yes, we offer technician-led on-site training for your team. Additionally, we provide

competitive online training covering maintenance and standard operating

procedures for the equipment.