X

- No products in the list

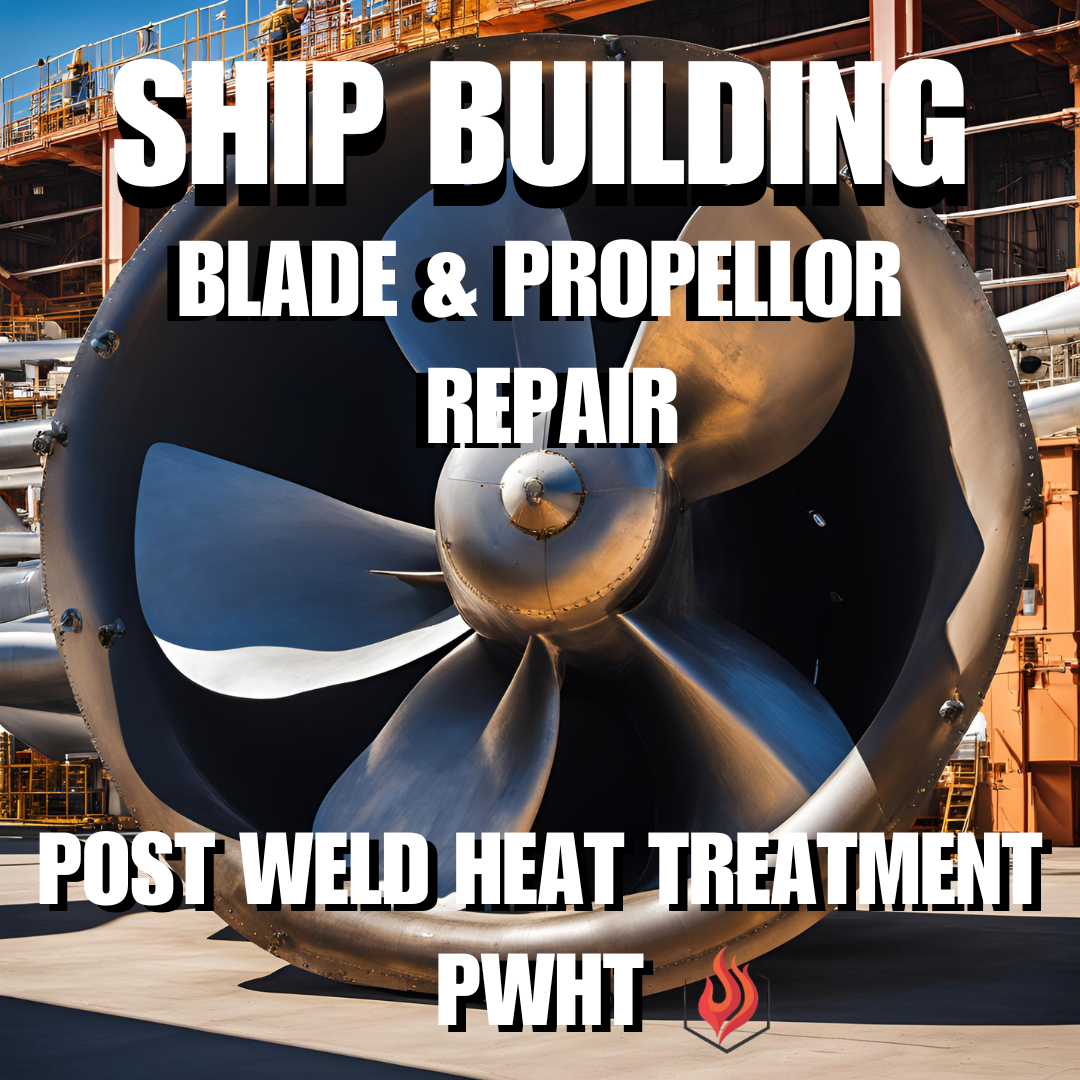

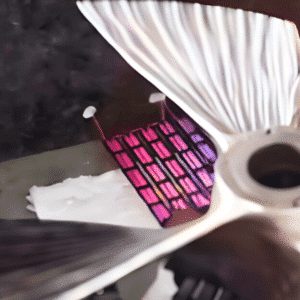

Ship propeller and blade repairs require precise post-weld heat treatment to ensure durability and performance.

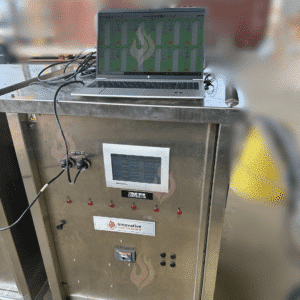

This case study highlights how a customized heat treatment solution addressed challenges like high-temperature control, complex shapes, and advanced monitoring technology, resulting in improved efficiency, cost savings, and enhanced component durability.

This combination of products and the new WPS enables shipbuilders to achieve high-performance welds that meet stringent standards, while also improving efficiency and reducing overall project costs.

These achievements underscore the effectiveness of the tailored heat treatment solutions in overcoming the challenges presented in this case.