X

- No products in the list

Innovative Heat Treatment – SNAKE– Heaters are engineered for temperatures up to 1150 C.( 2100 F)

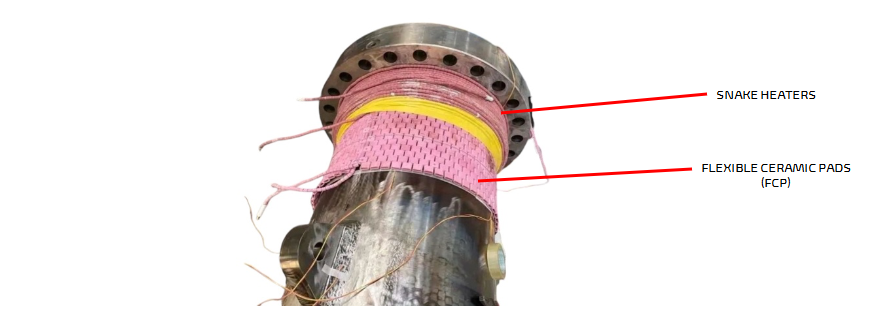

SNAKE HEATERS can be used for preheat and post weld heat treatment. They are robust and require minimal maintenance. Very effective for smaller areas require Pre-heat treatment and PWHT.

The wire has ideal resistive traits and is made of 80:20 Nickel Chrome.

Snake heaters have Flexible Wrap Design. Easily wrap around pipe joints and small areas . Especially aerospace PWHT and Miltary Heat Treatment Industry.

Typically used for post weld heat treatment of thinner wall pipe welds and preheating up 1,050C. They are also ideal for providing support heating on the edge of flanges for pipe to flange welds to compensate for the heat sink effect caused be the flange.

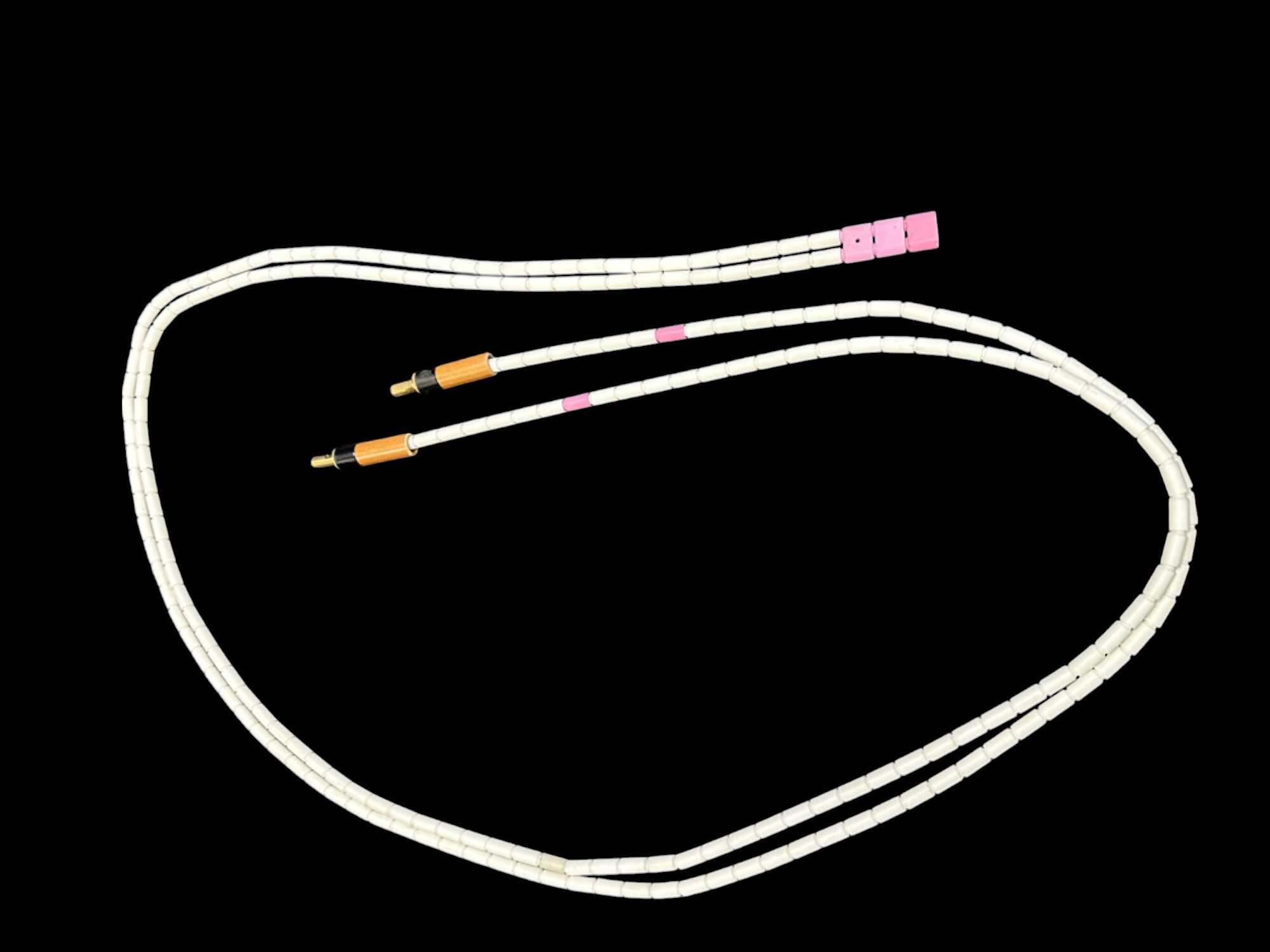

Strong heat transfer efficiency. Highly durable. Most importantly , we have indicated the Snake Heaters indicated by White beads. Usually about 8″ from the Camlock connector.

The tails are beaded with regular tail beads and a connector block is attached to the ends to make the connection with the power source cables.

Cold Tail : Indicates the transmission from Hot Tail to Cold tail. Noramly the connecting sleeve has.

Shell flexible and Heat-Resistant,

They have the Option of being equipped with the “DINSE” plug system or also with the standard English Camlock system, if required.

SNAKE HEATERS– are very flexible, Durable and often used SMALL AREA APPLICATIONS.

1) SMALL AREAS TO BE HEAT TREATED

2) Wrap around – circular Turbines & aerospace parts

3) High-temperature aerospace heat treating

4) Heat Treating on the edge of flanges

They provide an excellent and reliable means of PWHT ( Post Weld Heat Treatment ) when positioned

DESCRIPTION:

SNAKE HEATER

DIMENSIONS

1″ X 2.5″ (3 BEADS)

1″. ( X-AXIS )

2.5″ ( Y-AXIS )

CERAMIC PAD HEATER “Snake”

85″ HOTTAILS,

9″ COLDTAILS,

POTTED-END

SPECIFICATION:

80V

45A

| CATALOG# | 20901 |

| VOLTAGE | 80 |

| KW | 3.6 |

| LENGTH (Meters)/Feet | 1" x 0.8" (1 bead) |

| WIRE | 80:20 NI CHROME WIRE |

| Cold Tail | 200mm / 7.8" |

| Hottails | 107" |

| Amps | 49amps |

| CATALOG# | 20902 |

| VOLTAGE | 80 |

| KW | 3.6 |

| LENGTH (Meters)/Feet | 2" x 1.625" (2 bead) |

| WIRE | 80:20 NI CHROME WIRE |

| Cold Tail | 200mm / 7.8" |

| Hottails | 105" |

| Amps | 49amps |

Yes, you can use Standard Pads with SNAKE Pads but they must remain mutually Exclusive.

Leave the application on our website or by phone

The manager will contact you for further details

We will gladly deliver your order soon