X

- No products in the list

In the oil and gas industry, maintaining wellhead equipment’s integrity is crucial for safety and efficiency. This case study explores how pre-heat treatment techniques help preserve the structural integrity of wellheads, a vital part of the assembly.

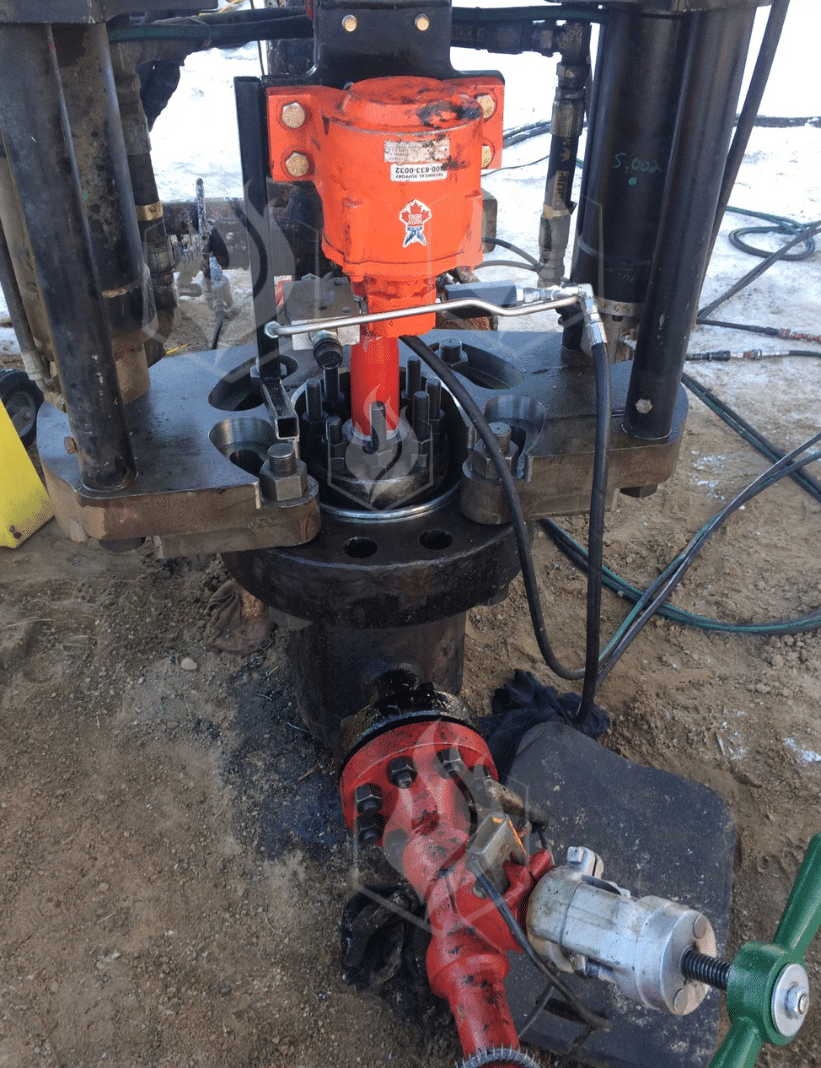

Effectively heating a tubing hanger to facilitate the separation of a Wellhead without compromising the structural integrity of the assembly.

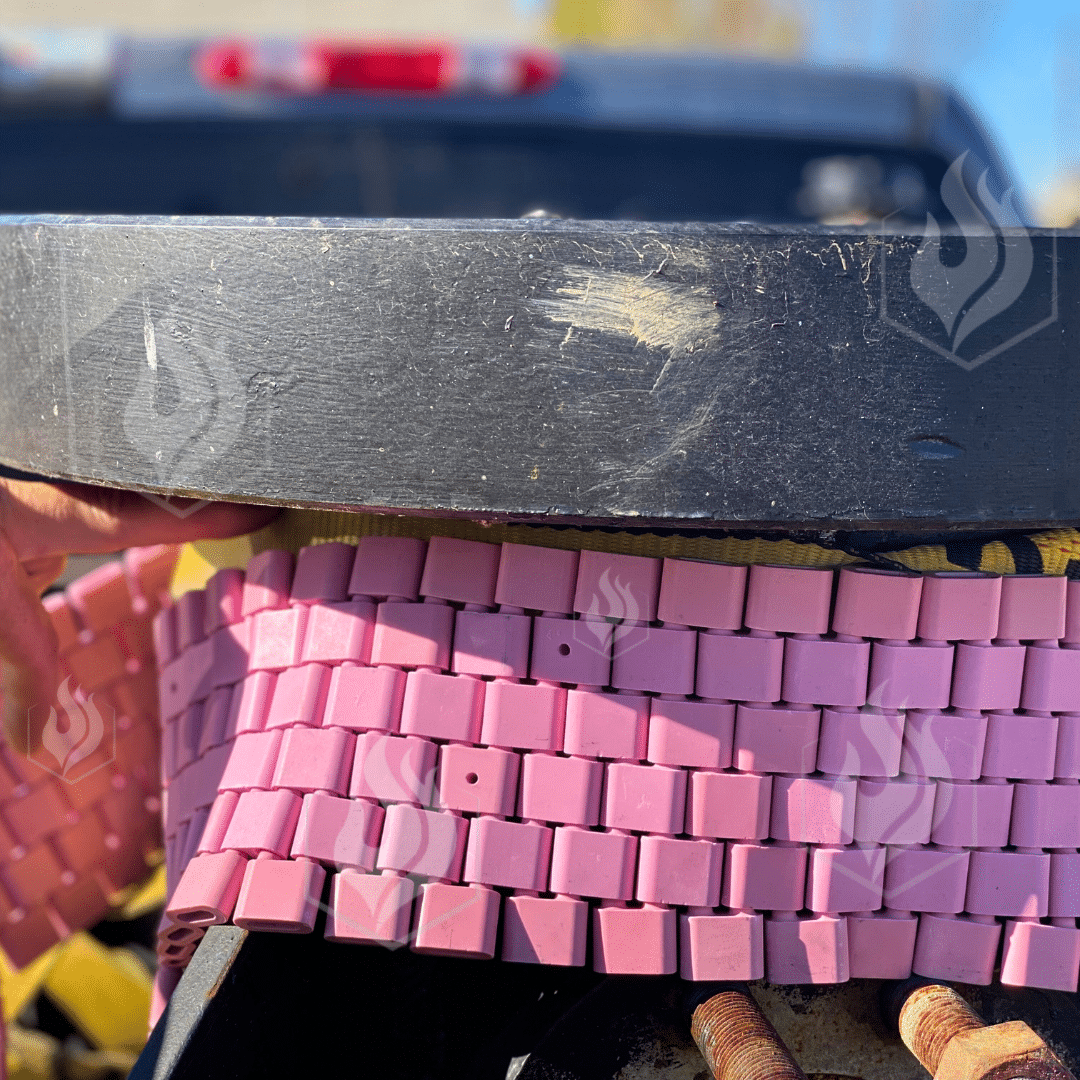

Requires an onsite solution for localized heat treating with the need to heat the component for aproximately one hour at 300°F

In order to address the challenge presented, we reccomended the following product solutions;

The clients approach involved a sequence of carefully planned steps:

The use of Flexible Ceramic Pads for pre-heat treatment in wellhead repair provided a controlled and effective heating method, crucial for preparing the metal for welding.

This approach ensured that the repair was performed safely and effectively, maintaining the structural integrity of the wellhead.

The four built-in, high-strength limpet magnets are rated to withstand

temperatures up to 250°C (482°F) with a 35 lb pull. The magnets will begin to lose

magnetic pull at this temperature. If you require stronger magnets, please

consider our pro-series magnetic pads designed for Post Weld Heat Treatment

(PWHT).

These are designed for Post Weld Heat Treatment (PWHT)

https://innovativeheattreatment.com/product/proseries-magnetic-ceramic-

heating-pads/

Yes, you can. Normally, there is 2”-4” spacing between the flexible ceramic pad

and the insulation. We can adjust the insulation length or add to it based on your

requirements.

Repair teams report a saving of about 60 % of the setup ups time.

Yes, we offer technician-led on-site training for your team. Additionally, we provide

competitive online training covering maintenance and standard operating

procedures for the equipment.