Menu

X

- No products in the list

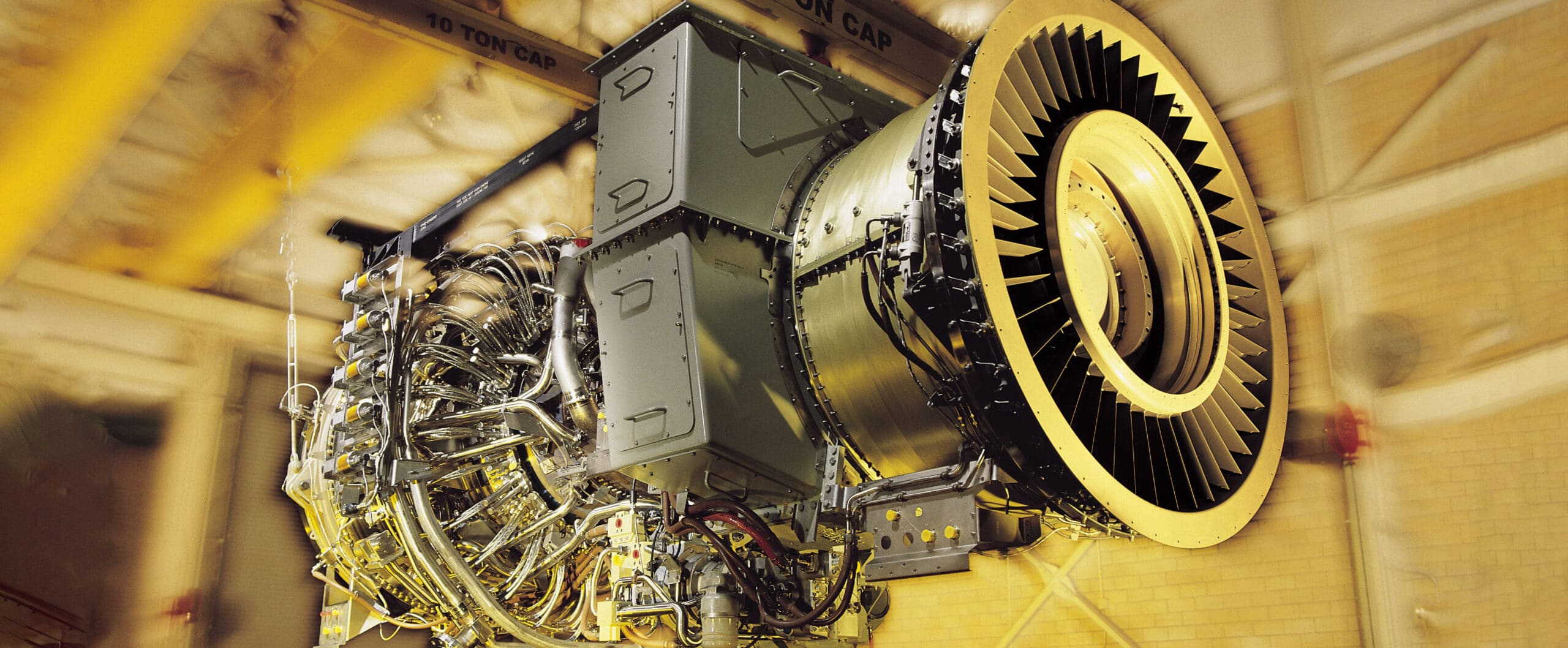

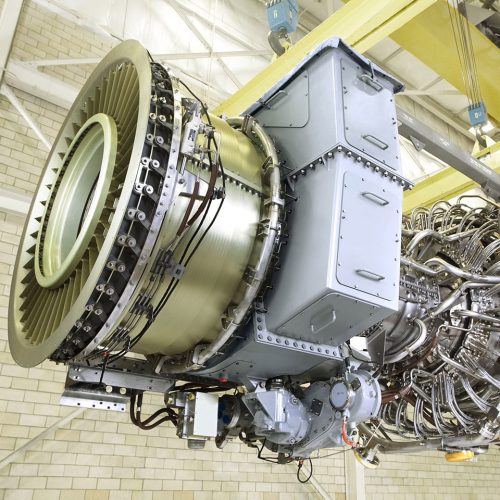

Our case study explores the impact of non-standard Aerospace postweld heat treatments (PWHT) on aeroderivative gas turbines, revealing notable time and cost savings through innovative solutions.

Goal:

The clients objective is to implement a customized PWHT solution.

Requesting an onsite and mobile solution for localized heat treating with the ability to heat up to 800 deg C.

The client is looking to accelerate the process while also reducing costs.

All equipment used is required to be ISO9001, CE, and CSA certified.

Key Issue:

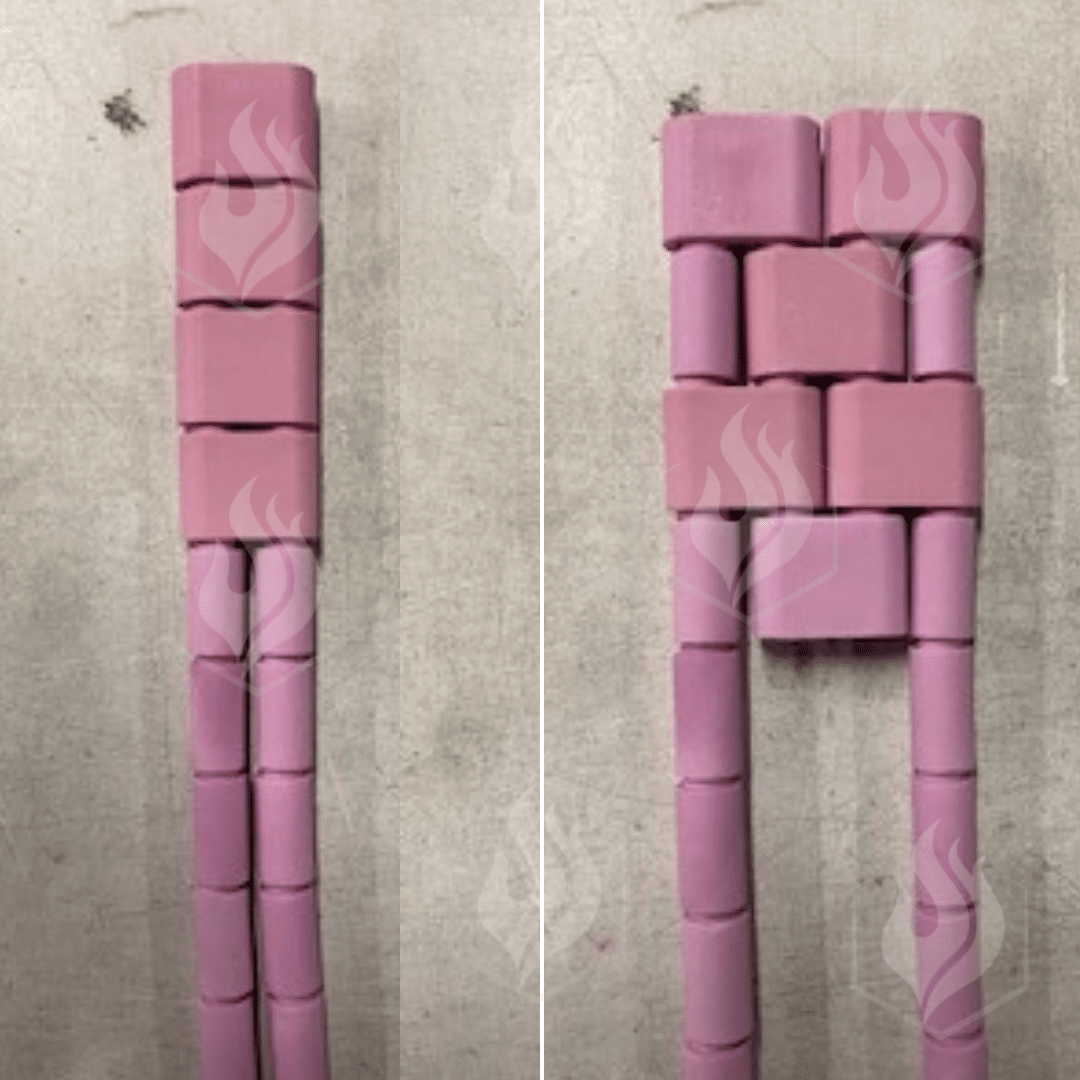

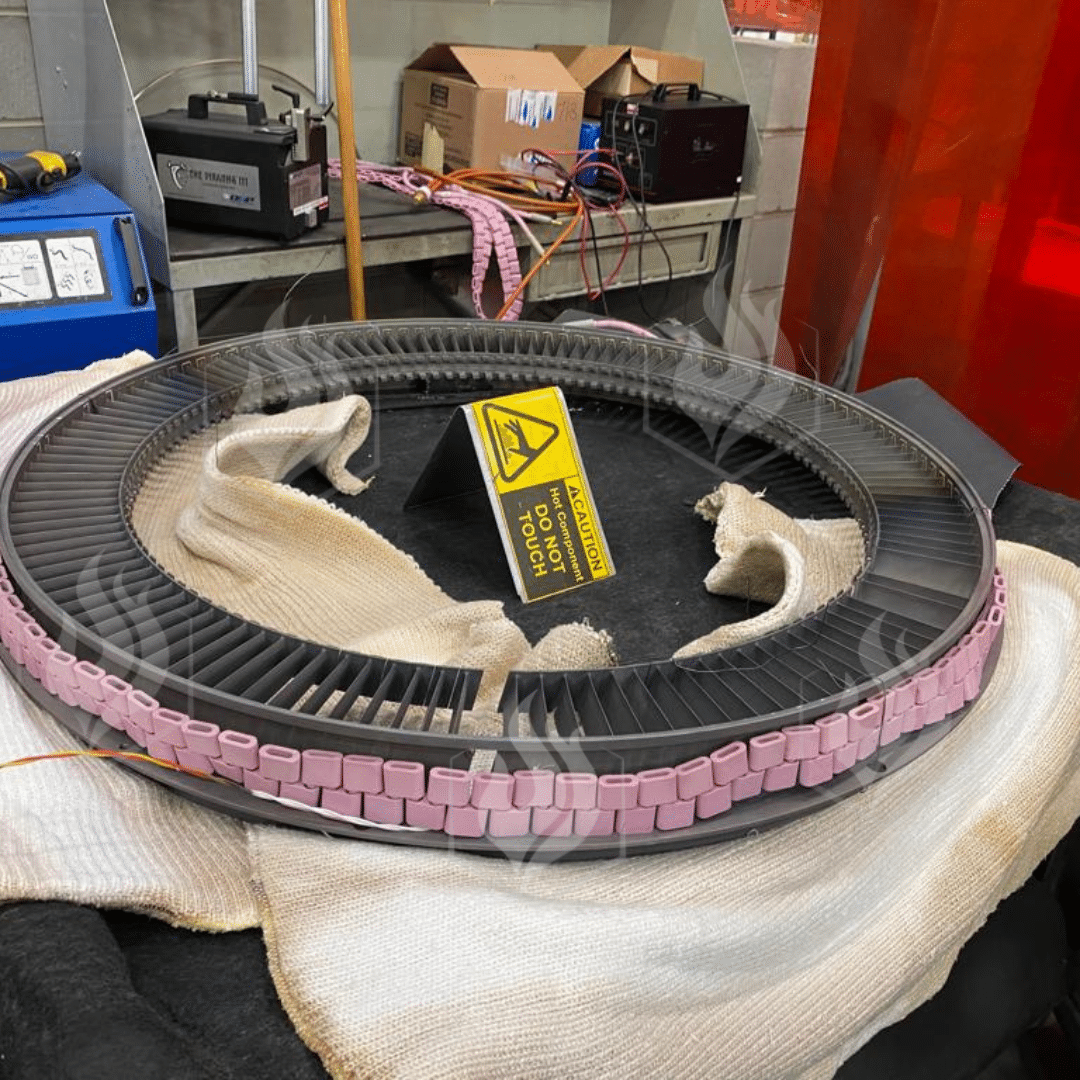

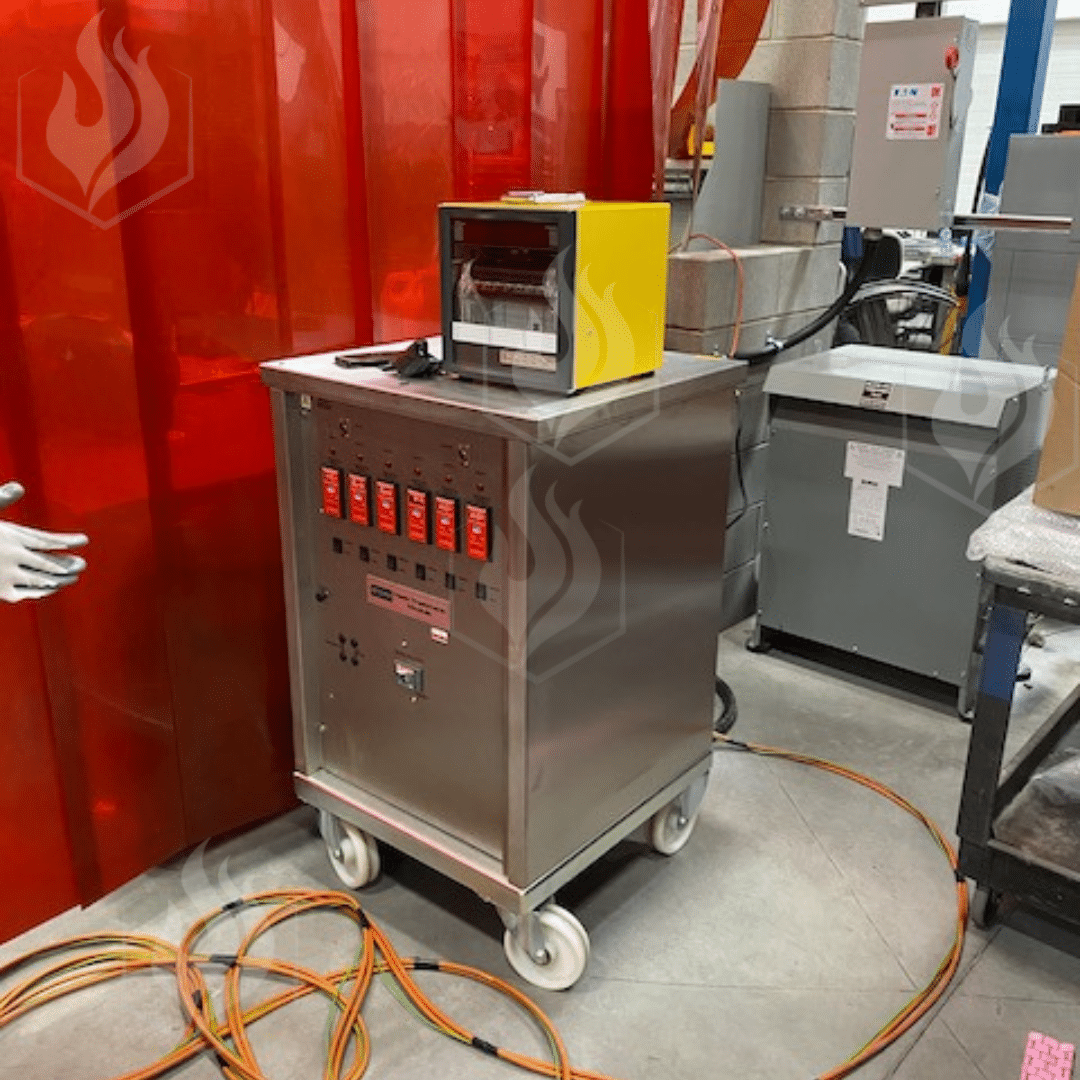

To tackle the requirement for certified mobile equipment, we suggested using 40 Volt Bespoke Heaters paired with the Chino Paper & Digital Recorder .

This setup accelerated the repair procedure by providing mobile, on-site equipment for Post weld heat treatment, eliminating the need to transport aerospace components to a separate heat treatment facility.

The client’s adoption of Bespoke Heaters and a Chino Recorder for on-site post weld heat treatment eliminated the associated costs and time of transporting aerospace components to an external heat treatment facility.

Our innovative solution yielded faster repairs, ensured standard compliance, and resulted in significant cost

The four built-in, high-strength limpet magnets are rated to withstand

temperatures up to 250°C (482°F) with a 35 lb pull. The magnets will begin to lose

magnetic pull at this temperature. If you require stronger magnets, please

consider our pro-series magnetic pads designed for Post Weld Heat Treatment

(PWHT).

These are designed for Post Weld Heat Treatment (PWHT)

https://innovativeheattreatment.com/product/proseries-magnetic-ceramic-

heating-pads/

Yes, you can. Normally, there is 2”-4” spacing between the flexible ceramic pad

and the insulation. We can adjust the insulation length or add to it based on your

requirements.

Repair teams report a saving of about 60 % of the setup ups time.

Yes, we offer technician-led on-site training for your team. Additionally, we provide

competitive online training covering maintenance and standard operating

procedures for the equipment.