Menu

X

- No products in the list

This success story demonstrates how pre-heating treatment products can simplify the repair process of mining equipment. It aims to improve structural strength, minimize repair times, and speed up turn around of equipment to the field.

Goal:

The client aimed for a Simplified Pre-Heat Treatment solution that minimized repair times, and improved structural strength. The equipment required to be operational and back in the field as soon as possible.

Key Issue:

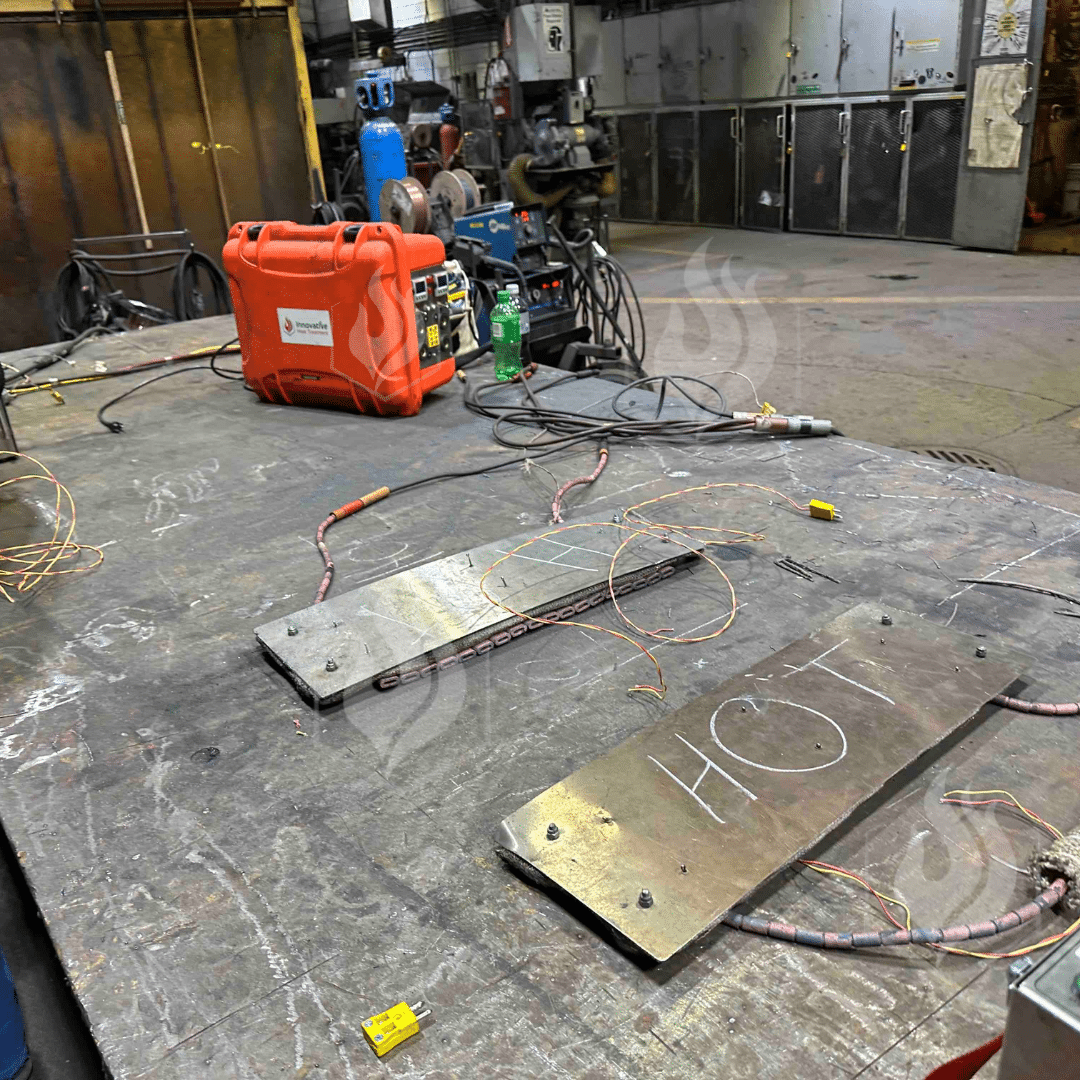

To address the challenge of repairing mining equipment, we recommend Magnetic Ceramic Pads along with the Twin Heat Module for Pre-Heat Treatments.

This method simplifies the repair process, allowing for quick attachment of the pads using magnetism, avoiding the more tedious traditional methods.

Twin Heat Module provides accurate and efficient control of heat to the equipment.

Switching to Magnetic Ceramic Pads and the Twin Heat Module cut down repair times by 60% and got the mining equipment back into action more durable than before, meaning the equipment will require repairs less often.

This method sped-up the process with quick magnetic attachment and precise heat control of the Twin Heat Module.

The four built-in, high-strength limpet magnets are rated to withstand

temperatures up to 250°C (482°F) with a 35 lb pull. The magnets will begin to lose

magnetic pull at this temperature. If you require stronger magnets, please

consider our pro-series magnetic pads designed for Post Weld Heat Treatment

(PWHT).

These are designed for Post Weld Heat Treatment (PWHT)

https://innovativeheattreatment.com/product/proseries-magnetic-ceramic-

heating-pads/

Yes, you can. Normally, there is 2”-4” spacing between the flexible ceramic pad

and the insulation. We can adjust the insulation length or add to it based on your

requirements.

Repair teams report a saving of about 60 % of the setup ups time.

Yes, we offer technician-led on-site training for your team. Additionally, we provide

competitive online training covering maintenance and standard operating

procedures for the equipment.